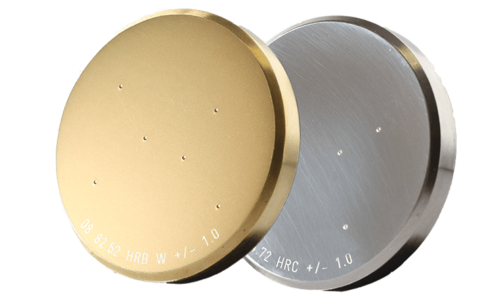

Wilson Rockwell hardness test blocks set the standard for the industry and are made from the highest quality material to insure the most uniform and repeatable Rockwell test blocks available. A comprehensive variety of scales and hardness test blocks are available to meet the wide ranges and hardness scales associated with Rockwell®, Brinell, Knoop and Vickers testing. All Wilson Rockwell hardness test blocks are calibrated in the Wilson Hardness Calibration Laboratory in Binghamton, NY. The Wilson lab is accredited to ISO/IEC 17025 by A2LA and the testers used in the calibration process undergo a stringent monitoring process using NIST traceable devices.

For the ultimate accuracy and performance in tester verification, calibration sets are available for most Rockwell scales.

100% inspection to ensure that every single Rockwell test block meets the physical requirements of ASTM (thickness, flatness, parallelism, surface roughness)

- We work directly with the steel and brass mills to specify the chemical composition

- Our machining processes (grinding, lapping, polishing) are all done in house, at the site of calibration.

- 100% inspection to ensure that every single test block meets the physical requirements of ASTM (thickness, flatness, parallelism, surface roughness)

- Rockwell test blocks support NADCAP compliance