Imaging Software for Routine to Advance Imaging & Microscope Automation

You and your team have the same goal in industrial quality control and materials research: To deliver reliable results with confidence. Speed, efficiency, and precision drive your team, powered by a software that facilitates their daily tasks. Leica Application Suite X (LAS X) from Leica Microsystems is the software platform for straightforward imaging and documentation in industrial applications.

-

Focus on your sample with exclusive full screen image

-

Show and expand the function buttons you need

-

Customize report templates for your test protocols

-

Set up individual user profiles to configure the microscope and camera according to operator’s skills

Clear, comprehensive, customizable

Software should make your standard tasks faster, easier, and more efficient; not more complicated. LAS X has a tidy user interface and navigation that makes workflows self-evident, intuitive and easy to learn for anyone in your team.

Use the full screen to view your sample

-

Focus on your sample in full screen size – the function buttons turn transparent when not needed

-

Activate the function buttons (e.g. for illumination settings, camera, measurements) with a single mouse click

-

Be confident that nothing is lost with our autosave function

One click. Report done.

LAS X offers you a wide range of report templates.

You can customize the templates according to your needs and share them with your team. This ensures that your team delivers reports that are consistent with each other.

Create reliable reports

Creating reliable reports on your measurement results has never been easier.

-

One click to export reports

-

Adapt the report templates to suit your test protocols

Store and Recall

Being able to reproduce your work is important for many applications.

Easily reproduce settings

With a single click, you can easily reproduce previous microscope settings and imaging parameters.

Tailor-made user profiles

A team is made of multiple individuals, with different levels of microscope skills and specific tasks to fulfill.

Difficult to handle for the supervisor? No!

Profiles according to the skills

LAS X enables supervisors to create user profiles according to the skills and the tasks of individual team members – from microscopy beginner to expert.

This ensures your team gets the reliable results you expect.

Choose the right tool

Leica LAS X offers a range of additional software modules and expert solutions for specific applications. This allows you to tailor your microscope system into a dedicated high-performance tool for current and future challenges.

Our global team of application specialists would be happy to advise you on the optimal choice of software modules.

Find out how our software modules can support your application

-

Image Acquisition & Documentation for single images

-

Acquisition, Measurement & Analysis in 2D and 3D

-

Metallography

LAS X Software Modules for Industrial Applications

Microscopy tasks in industrial applications such as quality control and quality assurance, failure analysis, research and development as well as materials science and forensics are varied and diverse. From image acquisition to reporting, software plays an integral part every step of the way.

To provide the specific software capabilities you need, Leica Microsystems offers modules that complement the LAS X software. Choose from a range of software modules – see below for more information on what our modules can do for you.

If you require additional information or advice, please so not hesitate to contact us.

Extend LAS X capabilities in image acquisition and documentation of single images

|

Name |

Description |

|

LAS X User Management |

Create user groups with different access levels. Allow or restrict individual functionalities for respective access levels. |

|

LAS X Extended Annotation |

Annotate your images with text in various fonts and colors, graphics, or measurements. |

|

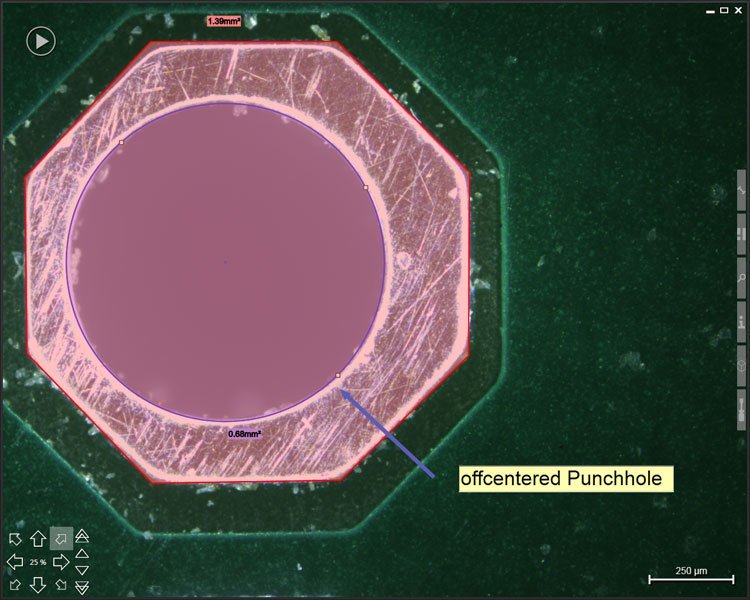

LAS X Measurements |

Measure parameters such as length, area, diameter, angle, or perimeter of objects you mark with adjustable tracing lines, drawing directly in the live images. Add labels for easy analysis. Apply measurements to several images to determine statistical trend and compare data in measurement templates. Apply long-distance measurements that span more than a single field of view. |

|

LAS X Reticule |

Display digital reticules, such as grain size, lines, circles, cross hairs and counting grids, on real-time images as electronic overlays for inspection, measurement, point counting, and comparison. Unlike eypiece reticules, digital reticules adjust to the magnification or zoom of the microscope. |

|

LAS X Live Stream Movie |

Capture images at set time intervals automatically to create movies to stream. Download as individual images or AVI files. |

Extend LAS X capabilites in image acquisition, measurement and analysis in 2D and 3D

|

Name |

Description |

|

LAS X Live Image Builder |

Create images that are bigger than a single field of view. Obtain a single in-focus image, if shallow depth of field provides only a partly focused image. |

|

LAS X Z-Control & SW Autofocus |

Create a single sharp image by capturing a stack of images at different focus positions and combining them automatically into an Extended Depth of Focus (EDOF) image. |

|

LAS X Extended Depth of Field |

Create sharp 2D images from several partially in-focus images. In connection with the 3D Surface Viewer, creation of 3D images is also possible. |

|

LAS X Stitching |

Create 2D images from multiple tiled images captured automatically. Obtain a spiral scan to capture only the region which interests you most. Single images can be retreived and analyzed with LAS X 2D Analysis. |

|

LAS X 3D Surface Viewer |

View 3D surfaces created from LAS X Extended Depth of Field. |

|

LAS X 3D Surface Measurements |

Measure 3D surfaces created from LAS X Extended Depth of Field in the LAS X 3D Surface Viewer. |

Extend LAS X capabilities in metallography

|

Name |

Description |

|

LAS X Nodular Cast Iron Expert |

Assess cast iron, adhering to industry standards including ASTM E247, ISO 945-2 and JIS5502. Use this software module for ductile irons to identify graphite nodules and place them into shape and size classes. Assess the ferrite and pearlite content and combine the results from these separate analyses. |

|

LAS X Decarburisation Expert |

Identify and analyse the depth of decarburisation in non- or low-alloyed steel. Automatically calculate the functional decarburization depth as a function of the amount present in the unaffected interior and your product specifications. |

|

LAS X Metallography Toolbox |

Assess, analyze, and measure metals, alloys, layers and coatings, adhering to laboratory requirements by incorporating analysis methods utilized in industry standards. Document your results in a Microsoft Excel report. |

|

LAS X Grain Expert |

Evaluate the properties of materials by analysing grain size to help determine the characteristics of the final product. The incorporation of industry standards ensures your analyses conform to your laboratory requirements. |

|

LAS X Phase Expert |

Measure multi-phase microstructures indentified by their distinctive color or contrast in materials and metallurgy laboratories. For example, reflectivity of components in oil-shale; polarisation colors of constituents in a thin rock section for modal analysis. Determine the occurrence of these phases with reference to the overall image or to one of the selected phases. |

|

LAS X 2D Analysis |

Detect, measure, and evaluate features and particles of powders, fiber cross-sections, pigments using a wide range of parameters. Use histograms, pie charts and statistics to illustrate results that can be exported to Microsoft Excel. |