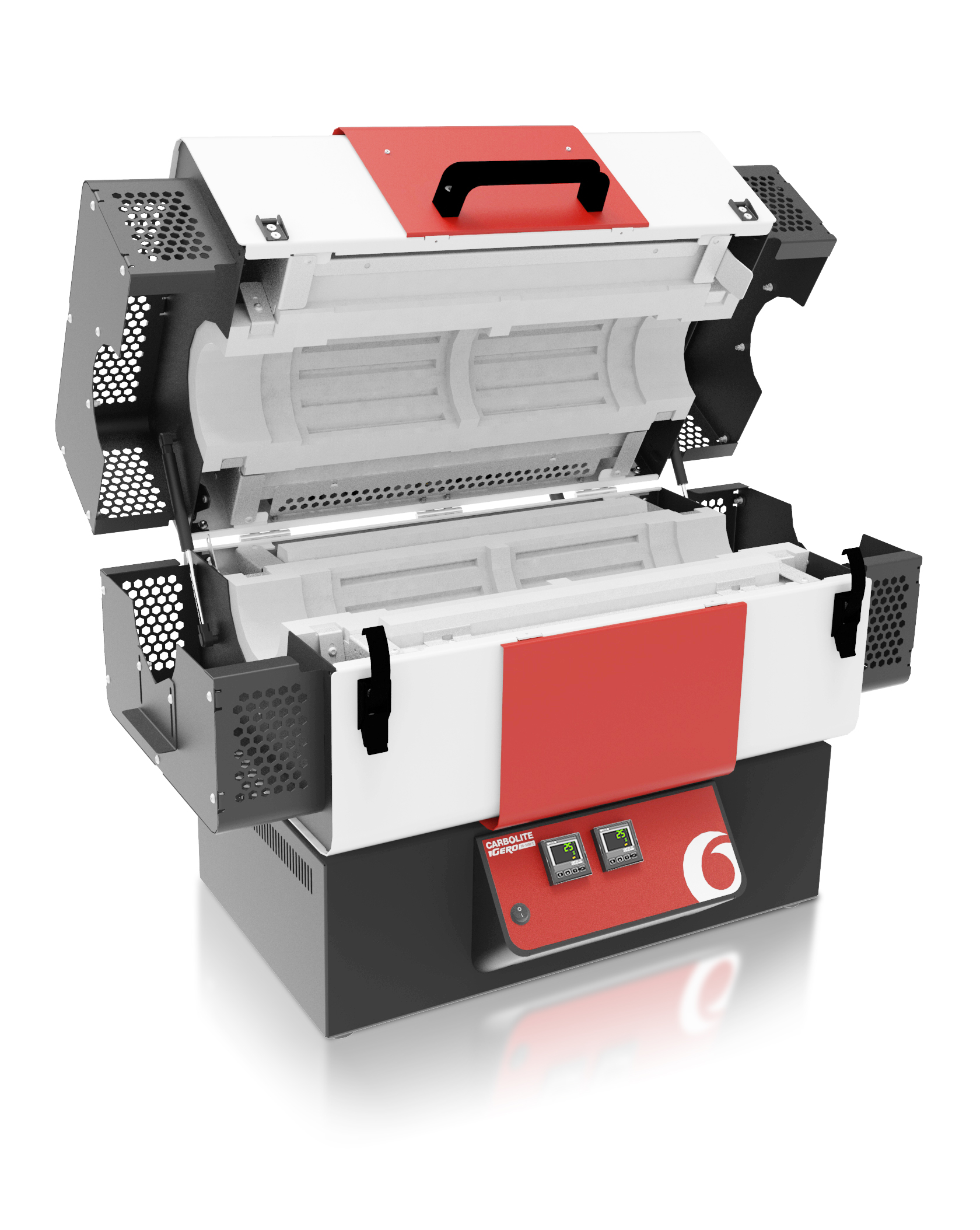

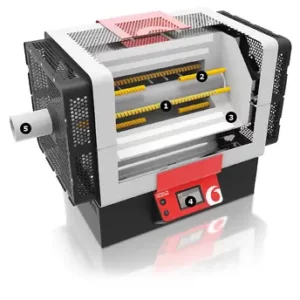

The TG Gradient Tube Furnace Range are compact split tube furnaces specifically designed to provide a temperature gradient along the length of the heated zones. They use free radiating wire elements embedded within the insulation of the furnace body. The benefit of this design is its flexibility; with tube adapters, the same furnace can be used with various tube diameters.

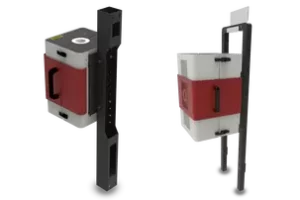

The furnace body is split into two halves and hinged at the rear; pneumatic dampening struts at either end provide a smooth opening. The ability to open the furnace makes it easier for operators to exchange work tubes or insert vessels, such as reactors, with end flanges that would make them difficult to insert into a non-split furnace.

The TG2 tube furnace includes a 25 mm long unheated zone barrier between the two 200 mm heated zones, while the TG3 includes two 75 mm long unheated zone barriers between the three 150 mm heated zones. Each heated zone has its temperature controller and thermocouple.

Carbolite Gero’s new tube furnace range is at the pinnacle of furnace design. The culmination of over 80 years of experience in thermal engineering, combining the latest technological developments with solid construction, high-quality components and a sleek, modern aesthetic.

HIGH-QUALITY HEATING ELEMENTS

- Excellent temperature uniformity

- Fast heat-up and cool-down rates

- Unsurpassed temperature uniformity along the entire heated length

HIGH-QUALITY THERMAL INSULATION

- Low energy consumption

- Low external case temperature

- Designed for longevity

TEMPERATURE CONTROL & COMMUNICATIONS

TG gradient tube furnaces are equipped with RS485 communications and a Carbolite Gero EPC3016P1 programmable temperature controller with 24 segments for each heated zone as standard.

TG gradient tube furnaces are equipped with RS485 communications and a Carbolite Gero EPC3016P1 programmable temperature controller with 24 segments for each heated zone as standard.

OPTIONS

- Over-temperature protection (recommended to protect valuable contents and for unattended operation)

LOW ENERGY CONSUMPTION

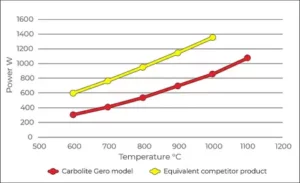

Carbolite Gero’s new tube furnaces are very energy-efficient. Their high-quality thermal insulation is designed for longevity, low case temperature and outstandingly low energy consumption. Using a Carbolite Gero tube furnace reduces your energy cost and carbon footprint.

UP TO 50% LESS ENERGY IS REQUIRED! COMPARISON WITH EQUIVALENT COMPETITOR PRODUCT

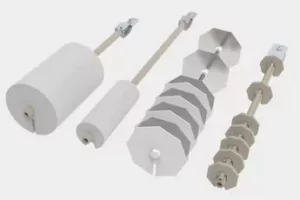

MODIFIED ATMOSPHERE & VACUUM EQUIPMENT

Carbolite Gero tube furnaces may have many options to accommodate modified atmosphere and/or vacuum applications.

OPTIONS

- A range of additional work tubes, end seals and complete work tube packages

- Vacuum packages with a choice of rotary vane pumps or turbomolecular pumps

- Inert gas package modules allow for the use of up to 3 non-reactive gases (available with either manual or automatic control)

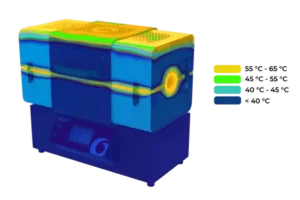

THAT’S COOL! LOW CASE TEMPERATURE

Carbolite Gero tube furnaces are designed with user safety in mind.

Carbolite Gero tube furnaces are designed with user safety in mind.

The robust construction and high-quality thermal insulation ensure that external case temperatures are much lower than in other models.

Not only does this help mitigate the risk of injury to the operator, but the reduction in the heat escaping the furnace ensures a comfortable working environment and means less energy is wasted during use. Carbolite Gero can help you keep a cool head when the heat is on!