Carbolite Gero’s TSR rotating tube furnace range incorporates the same innovations developed for the TS split tube furnace series with the equipment required to process large batches of free-flowing material, such as powders.

The TSR range comprises a split tube furnace horizontally mounted on a base frame, and fitted with a friction drive rotation system, allowing for work tube rotations of up to 10 rpm. The frame can be manually tilted up to a maximum angle of 6˚ to suit the requirements of the material being processed.

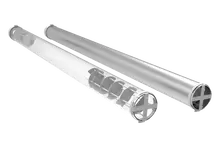

Accessory work tubes can easily be exchanged to meet a process’s different physical or chemical requirements. Optional built-in gas systems enable users to equip the TSR rotating tube furnace under a modified atmosphere.

Carbolite Gero’s new tube furnace range is at the pinnacle of furnace design. The culmination of over 80 years of experience in thermal engineering, combining the latest technological developments with solid construction, high-quality components and a sleek, modern aesthetic.

The rotating motion of the TSR helps increase the surface area of the sample material exposed to the atmosphere within the work tube, helping to speed up reaction times and improve the overall yield. A 5-litre capacity vibratory feeder and corresponding collection hopper make the TSR the ideal choice for continuous heat treatment processes.

HIGH-QUALITY HEATING ELEMENTS

- Excellent temperature uniformity

- Fast heat-up and cool-down rates

- Unsurpassed temperature uniformity along the entire heated length

HIGH-QUALITY THERMAL INSULATION

- Low energy consumption

- Low external case temperature

- Designed for longevity

Temperature Control & Communications

TSR rotating furnaces have ethernet communications and a programmable controller with 24 segments. Single zone furnaces are fitted with Carbolite Gero EPC3016P1 controller. Three-zone furnaces fitted with Carbolite Gero CC-T1 touch-screen controller.

TSR rotating furnaces have ethernet communications and a programmable controller with 24 segments. Single zone furnaces are fitted with Carbolite Gero EPC3016P1 controller. Three-zone furnaces fitted with Carbolite Gero CC-T1 touch-screen controller.

Options include:

- Over-temperature protection (recommended to protect valuable contents and for unattended operation)

- A range of sophisticated digital controllers, multi-segment programmers and data loggers is available

- fitted with RS232, RS485 or Ethernet communications

MODIFIED ATMOSPHERE AND MATERIAL MOVEMENT

The Carbolite Gero TSR rotating tube furnace may be equipped with gas connections to accommodate modified atmosphere applications. The gas system is built into the frame of the furnace, and the required gases and control method must be specified at the time of order. Options include manual flowmeters or digital mass flow controllers.

The TSR is available with a choice of different work tubes. Please note that the maximum operating temperature depends on the properties of the work tube material selected.

To accurately control sample material flow into the furnace, the TSR is fitted with a standard 5-litre hopper and vibratory feeder. A 5-litre collection hopper with a manual discharge valve is also included to gather processed material safely.

OPTIONS

- Gas connection kit to enable operation under modified atmospheres

- Inert gas package modules allow for the use of up to 3 non-reactive gases (available with either manual or automatic control)

- Input hopper with screw feeder

ANGLE OF INCLINATION

To assist in the flow of material through the work tube, the TSR can be tilted to a maximum of 6° using the manual winding wheel. By adjusting the angle of inclination, the operator can control the residence time of the material within the heated zone of the rotating tube furnace; the ability to change the angle ensures that the TSR has the flexibility to process many different materials with various grain sizes, from granules to powder.

To assist in the flow of material through the work tube, the TSR can be tilted to a maximum of 6° using the manual winding wheel. By adjusting the angle of inclination, the operator can control the residence time of the material within the heated zone of the rotating tube furnace; the ability to change the angle ensures that the TSR has the flexibility to process many different materials with various grain sizes, from granules to powder.