Discover the World Beyond Your Sights

Ashing

Furnaces

Carbolite Gero’s ashing furnace range covers one of the most common applications for laboratory chamber furnaces: To heat combustible samples in order to analyse the resulting ash residue. As there is no single solution for all requirements, different furnaces tailored to ashing and burn-off applications are available.

Showing all results

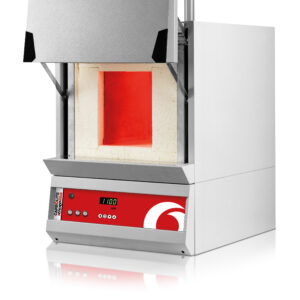

Carbolite AAF 3 and 7 Ashing Furnaces

- Max Temp: 1100°C

- Chamber volumes: 3 to 7 litres

- Comply with ISO 1171:2010, ASTM D3174-04:2010, ASTM D4422

- Max Temp: 1100°C - 1200°C

- Chamber volumes: 18 & 32 litres

- 2-tier rack and tray system

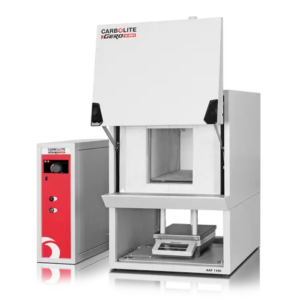

- Max temp: 1100°C

- Chamber volume: 17 litres

- Integral precision balance with 3kg capacity

- Max temp: 800 °C

- Chamber volume: 28 litres

- Integrated afterburner for further burning of fumes

- Max temp: 1100 °C

- Chamber volume: 8 litres

- Quartz silica chamber lining

Ashing Furnace - FAQ

WHAT IS AN ASHING FURNACE?

An ashing furnace is a type of chamber furnace designed to allow materials to be burned at a closely controlled temperature. Air is drawn into the chamber by the tall chimney and is forced to pass between the insulation layers so that it is pre-heated before entering the chamber. This ensures that samples near the air inlet are not cooled by the airflow and byproducts that could attack the elements are thereby flushed out of the ashing furnace.

WHICH APPLICATIONS REQUIRE AN ASHING FURNACE?

Ashing furnaces are frequently used in the testing of foods, plastics, and hydrocarbon materials such as coal. Tests may be defined within standard test methods, typical examples of which are ISO 1171:2010 and ASTM D3174-12.

WHAT IS THE DIFFERENCE BETWEEN A STANDARD LABORATORY CHAMBER FURNACE AND AN ASHING FURNACE?

The difference between a standard laboratory and an ashing furnace is primarily the supply of preheated air to promote burning. Ashing furnaces are specially designed to have increased airflow to facilitate the combustion and subsequent ashing of materials.

Subscribe

Known for service-excellence, we don’t just supply the tools, we assist you in gaining proficiency with our products through our dedicated training program.