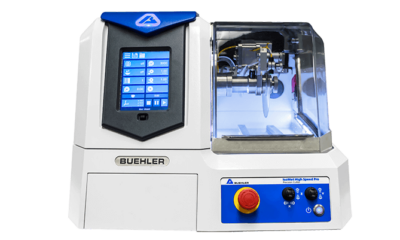

The Buehler IsoMet High Speed Pro is a table top precision saw that provides efficient and precise cuts with intuitive control. The innovative machine and vise designs make setup quick and simple. Align cuts quickly by using the precision laser, tool-less adjusting and the 3-axis blade movement. Precision and abrasive cut samples are now made quicker without impacting cut quality.

The IsoMet High Speed Pro has a blade motor power of 2kW, which is the strongest motor on the market. This motor power ensures the blade will minimize the deformation of the sample surface, saving you time later in the material preparation process. Reduce the cut time without impacting the surface quality.

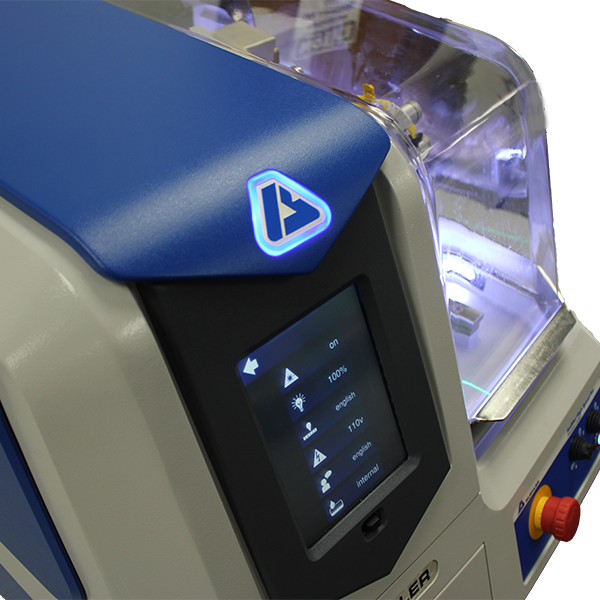

The IsoMet High Speed Pro has a variety of programmable capabilities. The simple user interface keeps the most important and frequently used features within one touch from the home screen.

Intuitive user interface

- Simple touch screen layout for quickly changing cut parameters

- Active icons to visually represent machine parameters

- To repeatedly perform a consistent cut, methods can be loaded and saved from the main screen

Highly reproducible results

- Automatic precision sectioning for consistent and repeatable results

- Program serial sectioning to make multiple cuts at a time

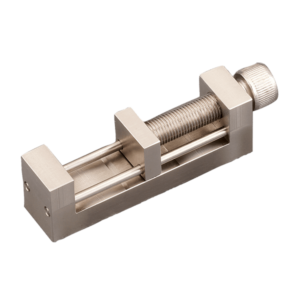

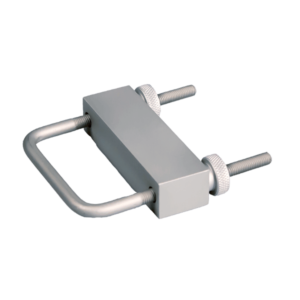

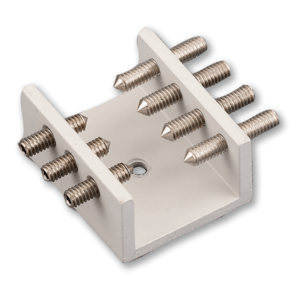

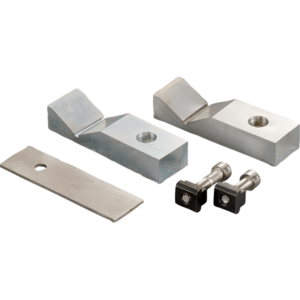

Quick Sample Adjustment

- In seconds adjust your sample placement with the rapid rail and vising system

- Visually align cuts with ease using the laser

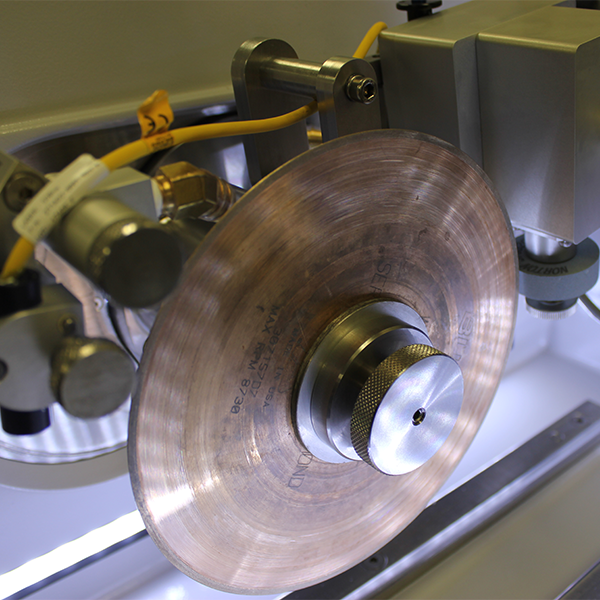

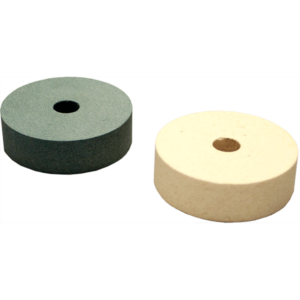

Excellent cut quality for delicate samples

- 2 micron precision cut alignment

- Cut delicate samples with precise accuracy

- Minimizes damage to system and sample with SmartCut™ by adjusts feed rate

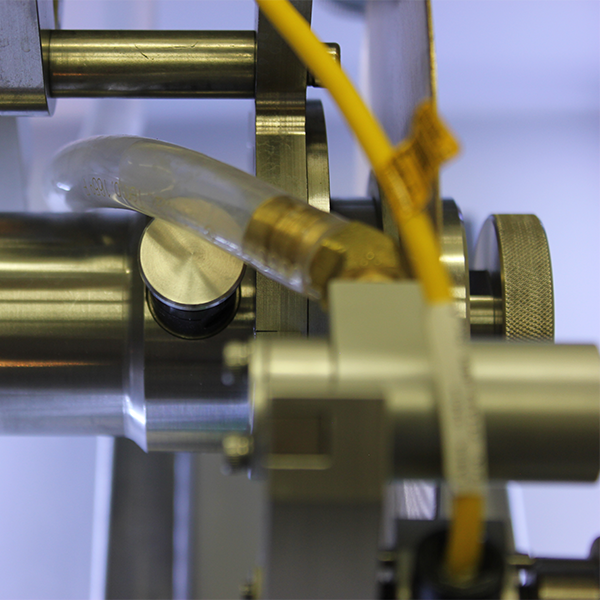

- Compatible with external recirculating system for abrasive sectioning

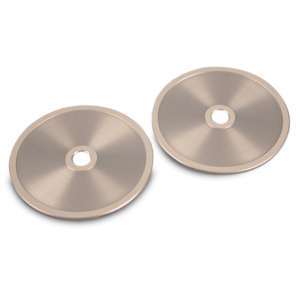

- For time savings, the automatic dressing system will keep your diamond blade cutting at optimal levels reducing sample deformation

Controllable cut quality

- Manual section samples with the precision controllers