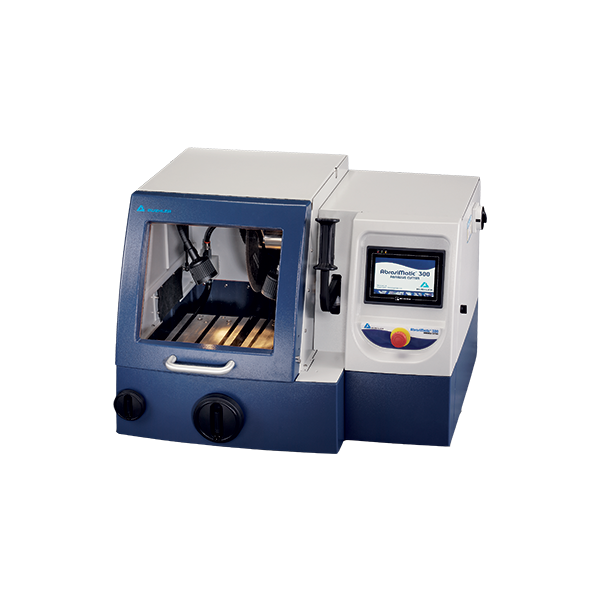

The AbrasiMatic 300 Automatic and Manual Abrasive Cutter is a benchtop dual abrasive cutting machine featuring manual cutting action in 3 directions or automated cutting in 1 direction. This abrasive cutter enables variety in sample preparation to best fit each sample process with both manual and automatic abrasive cutting capabilities. It is engineered with innovative capabilities to be used in both production support and laboratory environments.

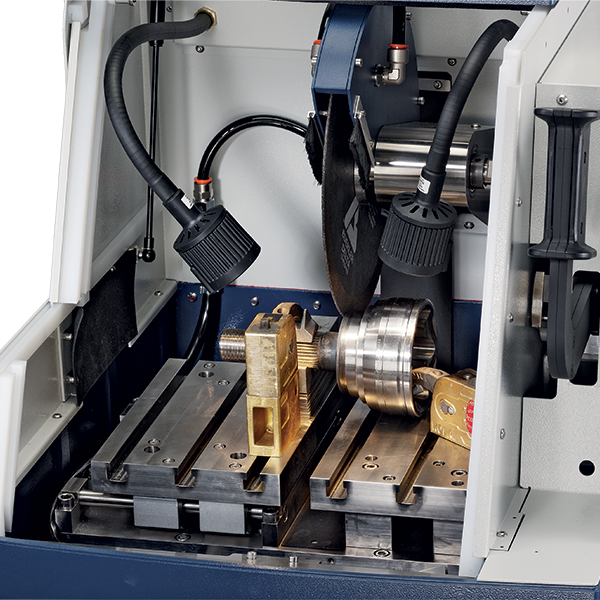

This manual and automatic abrasive cutting machine can handle the abrasive environment with a stainless steel T-Slot bed.

The AbrasiMatic 300 now includes an accompanying digital display to track X-axis travel improving precision, consistency and repeatability in serial sectioning applications.

Flexibility for changing lab needs

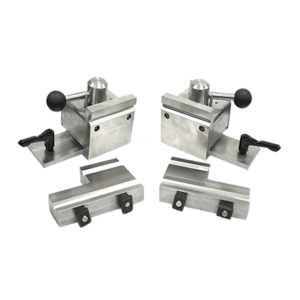

- Best of both cutting methods with manual and automatic cutting

- Control and “feel” of the cut with the manual cutting in the Y and Z direction

- Allow for sectioning of parts with a 4.5in diameter (varies based on part shape)

Highly reproducible results

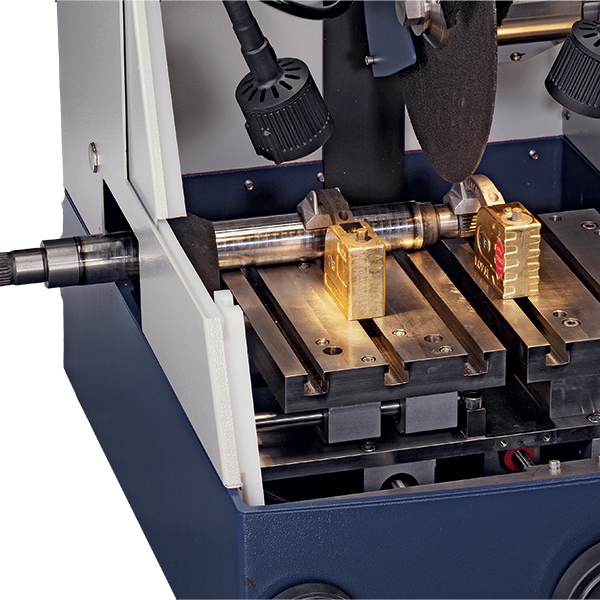

- Consistent and repeatable cuts with the automatic cutting in the Y direction

Simple setup for efficient cuts

- Quick vising and cut alignment with x-axis motion (optional)

- The simple user interface to program automatic cutting and set manual cutting

- The automatic cutting creates more time for critical activities

- Electrical brake for user safety and quick part change

Durable machine design

- A machine that can handle the abrasive environment with a stainless steel T-Slot bed