The AZ Tube Furnace is an eight-zone furnace for controlled temperature profiles. These zones can be used to generate temperature profiles along the heated length of the furnace.

With eight zones, thick insulation, and highly symmetrical winding of the heating elements throughout the entire AZ furnace, a uniformity of better than ± 5 °C is achieved. A key advantage of the eight individually controlled zones is the extension of the uniform length inside the furnace. Additionally, the temperature profile can be precisely controlled for linear increases, peaks, or other user-defined profiles.

One process well suited for the AZ tube furnace is chemical vapour deposition, as a temperature gradient can be established in the furnace for evaporation of precursor material at the high-temperature end zone and sublimation of the vapour onto the substrate at the cooler temperature end zone. All zones are individually controlled and monitored with thermocouples.

OPTIONS (SPECIFY THESE AT THE TIME OF ORDER)

- A range of sophisticated digital controllers, multi-segment programmers and data loggers are available. These can be fitted with RS232, RS485 or Ethernet communications – more information

- Over-temperature protection (recommended to protect valuable contents & for unattended operation)

- A wide choice of tube diameters and materials is available: eg quartz, ceramic, metal

- ‘L’ stand for vertical usage

- Insulation plugs & radiation shields to prevent heat loss & improve uniformity

- Modified atmosphere and vacuum assemblies are available – more information

- Vacuum packages with a choice of rotary vane pump or turbomolecular pump are available for furnaces with tube – inner diameters of 60 mm and above

- Complete automation by Siemens SPS control with touch panel and mass flow controller for the gases on request

- Other diameters and heated lengths on request

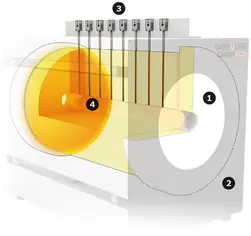

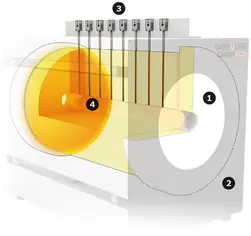

FUNCTION PRINCIPLE

View inside

View inside

- ceramic fibre insulation

- outer frame

- eight thermocouples for control

- usable volume

The ceramic fibre insulation is constructed in multiple layers and assembled with great care to ensure no gaps are present between each layer. The insulation layers are arranged with a specific overlap to provide excellent temperature uniformity inside the furnace.

The control module is very compact and built into the support frame of the furnace. A touch panel interface provides user-friendly and intuitive control of the furnace operating parameters.

No water cooling is necessary as the housing is spaced from the insulation and cooled by convective cooling. The only instances that require water cooling are for use with cooled work tube flanges, i. e. to assemble a vacuum pumping unit.

View inside

View inside