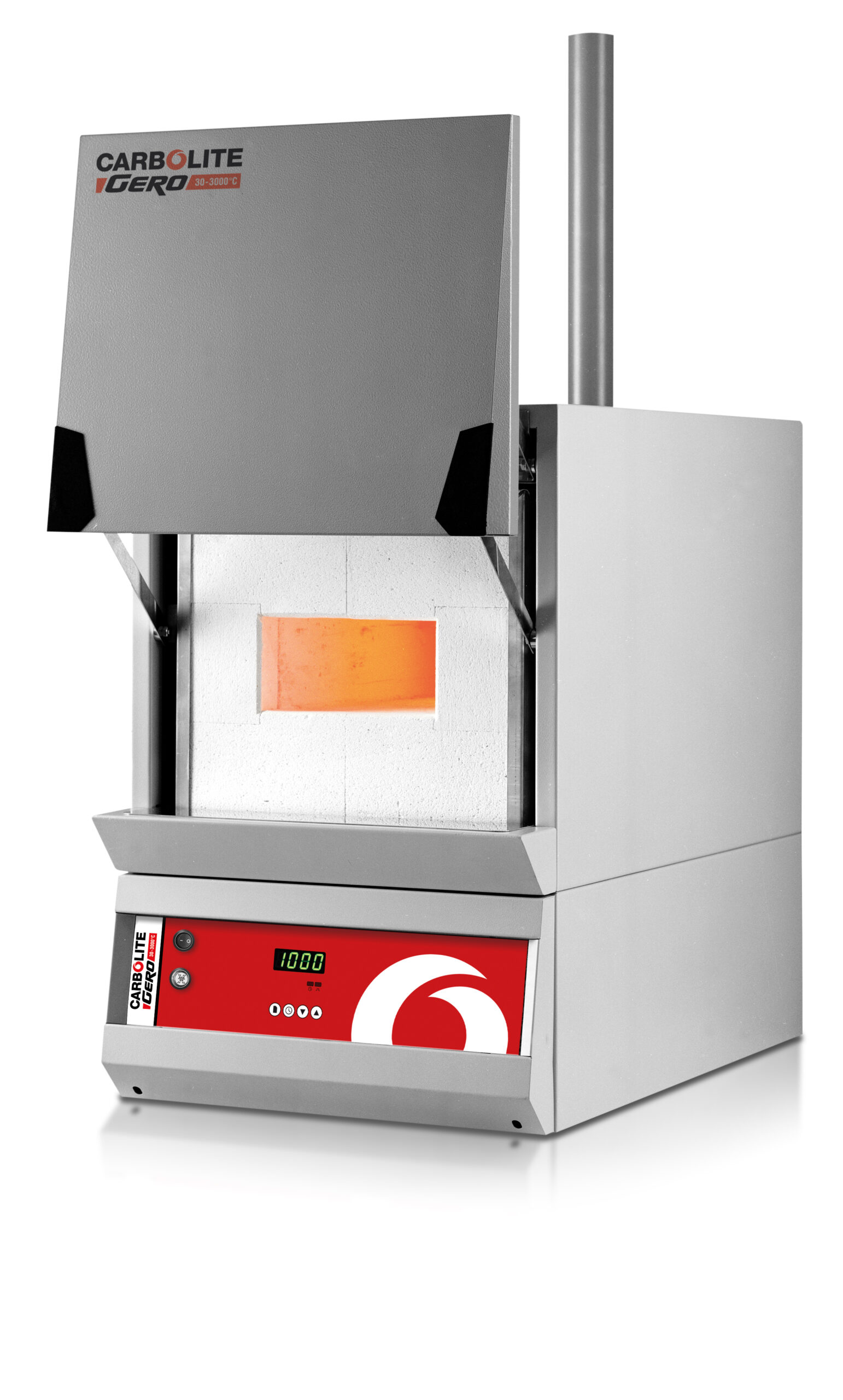

The AAF ashing furnaces range is specifically designed to create ideal ashing conditions, ensuring complete combustion of the sample. The AAF 11/3 and AAF 11/7 ashing furnaces consistently flow preheated air throughout the chamber while adhering to the ISO 1171:2010, ASTM D3174-04:2010 and ASTM D4422 standards.

Standard Feature:

- 1100 °C maximum operating temperature

- Carbolite Gero 301 single ramp to setpoint & process timer

- Large floor area allows for a large number of samples

- Ideal for ashing foods, plastics, coal & other hydrocarbon materials

- Designed to comply with ISO 1171:2010, ASTM D3174-04: 2010 and ASTM D4422

- Wire elements are protected from chemical & mechanical damage by a hard-wearing alumina-based liner

- 4 sided heating (2 sides, roof & hearth)

- Air inlet & tall chimney give airflow of 4 to 5 changes per minute

- Low chamber height holds airflow close to samples for optimum combustion

- Powerful elements with graded winding compensate for heat loss due to high airflow

- Preheating air, before it enters the chamber, gives excellent uniformity

- Sample tray and loading handle

Airflow in AAF 3 and AAF 7

1. A tall 50 mm diameter chimney (AAF 7), or 35 mm on AAF 3, pulls the air through the chamber

2. Preheated air enters the chamber after circulating around the outside of the chamber

3. Air inlet

Accessories for AAF 11/3 and AAF 11/7

1. AAF 11/3 tray

2. AAF 11/7 tray

3. Loading handle

Options (Specify these at the time of order):

- 2-phase electrical supply for AAF 11/7

- A range of sophisticated digital controllers, multi-segment programmers and data loggers is available. These can be fitted with RS232, RS485 or Ethernet communications (see pages 100 – 103, brochure)

- Over-temperature protection (recommended to protect valuable contents & for unattended operation)