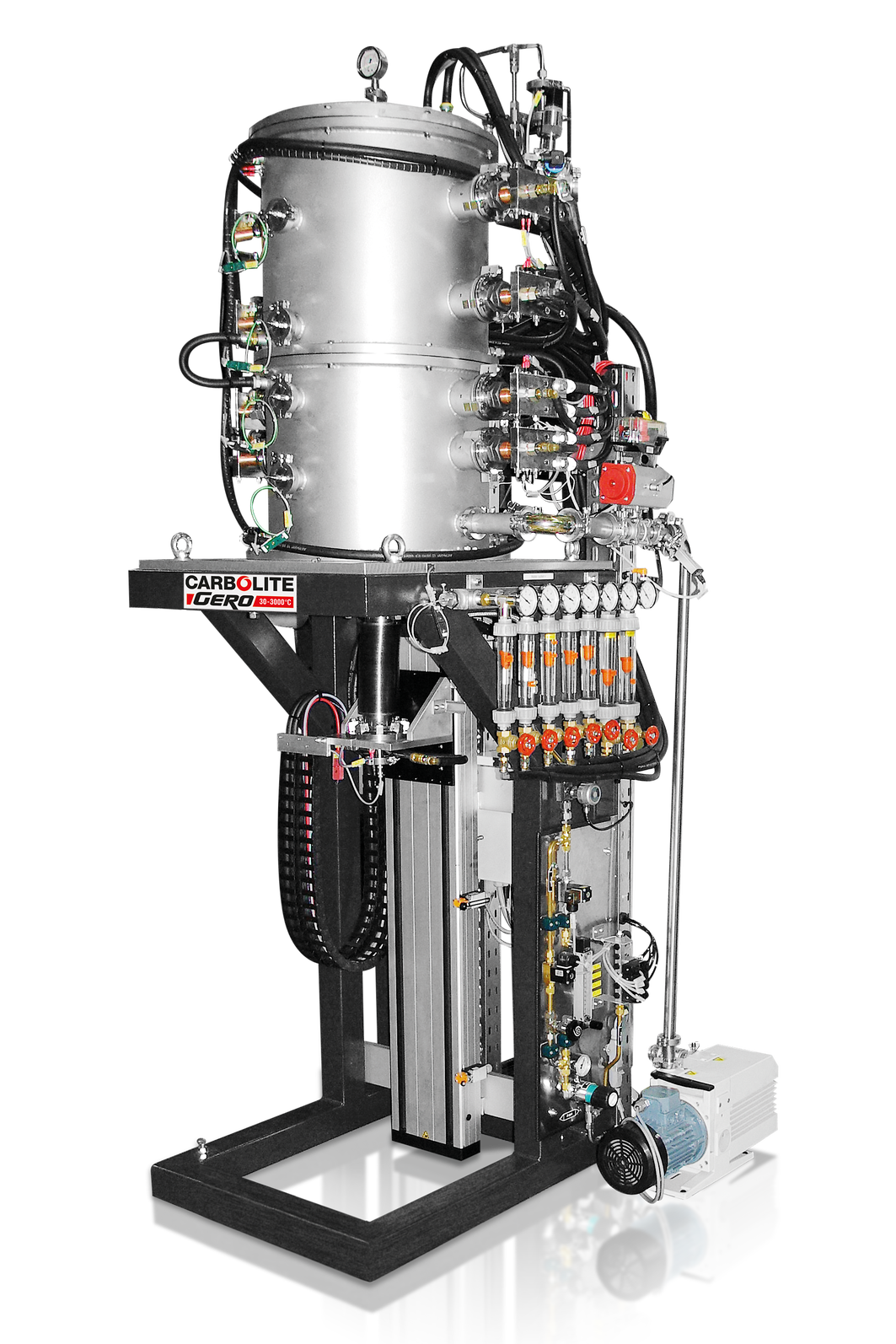

The BV-HTRV is a special crystal-growing furnace designed for the Bridgman method. This method uses pre-synthesized materials that move slowly through a temperature gradient to form a single crystal. The BV-HTRV is a tube furnace mounted on a device specifically engineered for this method. The standard models used are HTRV 70-250 or HTRV 100-250, but any tube furnace can be mounted on the pulling device. The short heated length of the BV-HTRV creates an ideal gradient for the Bridgman method, with the temperature decreasing towards the bottom of the furnace.

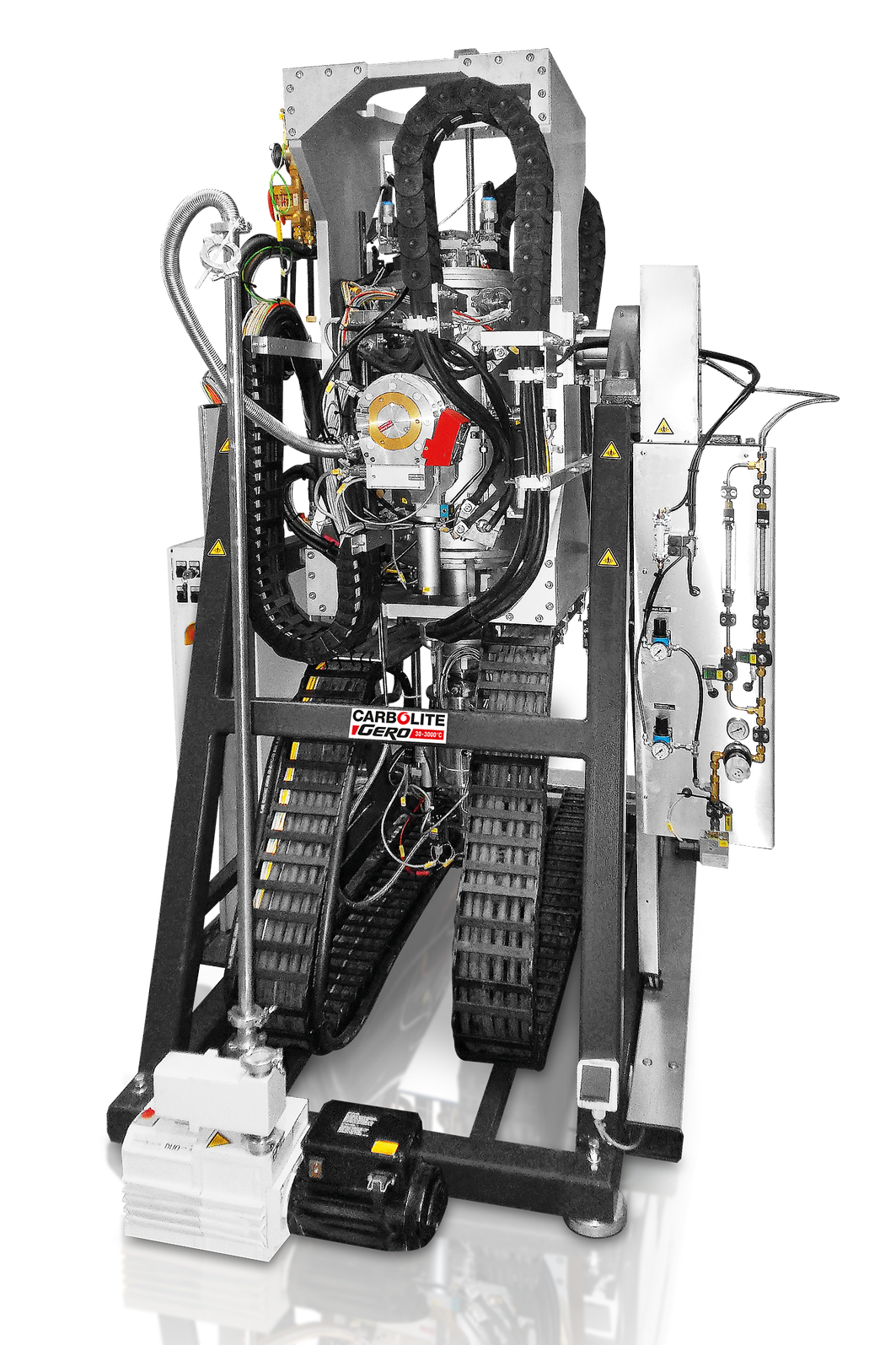

The pulling device moves the sample at an adjustable speed towards the lower temperature, while a thermocouple attached to the bottom pulling device gives an accurate reading of the sample temperature. Loading and unloading the sample can be fast, while crystal growth can be achieved with a user-defined speed. The probe thermocouple and sample are surrounded by a ceramic tube, with water-cooled flanges at both ends. The bellow is extended during the downward movement of the sample, while the vacuum pump and piezo measurement gauge control the vacuum level.

To reduce oxygen levels before the crystal growing process, evacuation and backflooding with an inert gas are performed several times. A computer can be connected to the system to log all relevant data, including the sample position and probe thermocouple temperature. To load and unload the sample, the clamps must be opened. The pulling device can be combined with all single and multi-zone tube furnaces.

Application Examples

Bridgman method, growing of single crystals

Standard Features

- Bridgman method – Crystal Growing

- In vacuum up to 1450 °C

- In an inert atmosphere up to 1800 °C

- Precisely defined and controlled pulling speed

- Manual operation

- Data recording option

Technical Details

The Bridgman Crystal Growth Furnace is equipped with MoSi2 heating elements that are mounted vertically and surrounded by vacuum-formed plates to insulate the heat from the housing. The housing has slots that allow for convection cooling. Depending on the sample’s melting point, the maximum temperature can be designed up to 1600°C, 1700°C, or 1800°C. For the pulling device, two motors with different transmission ratios are used. The crystal growth process is slow, with a pulling speed of only 0.00001 mm/s (10 nm/s), while faster speeds of approximately 10 mm/s are possible for moving the samples. All tubes connected to the lower water-cooled flange are inserted in a drag chain. The control thermocouple is a type B thermocouple. An overtemperature thermocouple is optional but highly recommended, especially if the crystal-growing process is left unattended for long periods. If temperatures higher than 1800°C are needed for Bridgman crystal growing processes, Carbolite Gero can provide custom solutions upon request. Please contact us for a free consultation. We are always happy to help.