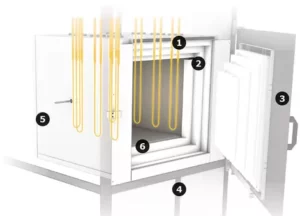

The HTF chamber furnace range for industrial is designed to operate at maximum temperatures of 1600°C, 1700°C, or 1800°C, and molybdenum disilicide elements heat it. The furnace is available in various sizes, ranging from 27 to 560 litres, and it comes with independent over-temperature protection as standard, allowing for safe, unattended operation.

It is important to note that the HTF furnace is only suitable for heat treatment in air. However, an additional gas supply can be provided upon request, resulting in slightly modifying the atmosphere inside the furnace that will suppress the oxygen levels. This feature makes HTF ideal for sintering ceramics and oxide ceramics.

For debinding before sintering, Carbolite Gero provides a debinding package for the HTF furnace. The debinding package includes an inlet for preheated air, several gas inlets, and an afterburner. The preheated air is symmetrically purged at several gas inlets into the furnace, which improves temperature uniformity at low temperatures and sample envelopment by the incoming air. All gaseous by-products generated during the debinding process are combusted in an afterburner driven by propane gas and compressed air. After the completion of debinding, the furnace temperature will increase to begin the sintering process.

APPLICATION EXAMPLES

annealing, ceramic injection moulding (CIM), debinding, debinding in air, degassing, drying, sintering, sintering in air, sublimation, synthesis, and tempering.

Standard Features

- 1600 °C, 1700 °C & 1800 °C maximum operating temperatures

- From 27 to 560-litre capacities

- Programmable EPC3016P1 controller

- Over-temperature protection

- High-quality molybdenum disilicide heating elements

- Advanced refractory interior, used in combination with energy-efficient low thermal mass insulation

- Automatic movement of the door

- Controller mounted on a user-friendly satellite

- Ethernet communications