The HTMA series comprises a range of modified atmosphere high-temperature ovens that maintain inert atmospheres up to 700°C. The HTMA ovens come equipped with separate flow controls for purging and process gases, allowing the process gas to be used at lower flow rates after the chamber has been purged of atmospheric air. The switching between purge and process gases can be done manually or by adding an automatic programmable control system. These ovens can achieve oxygen levels down to 50 ppm.

Standard Features

- 400°C, 500°C, 600°C or 700°C operating temperatures

- 28, 95, 220, 500 & 1000-litre capacities

- Carbolite Gero 301 controller, with single ramp to set-point & process timer

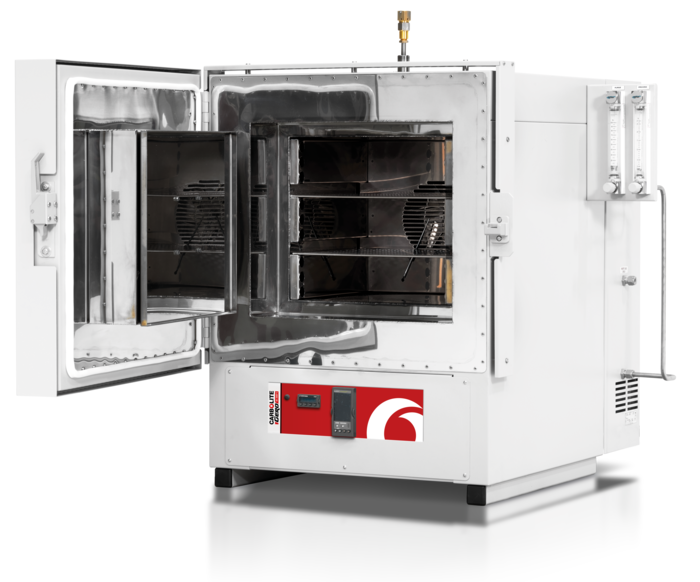

- Rear mounted fan & side air guides give horizontal ‘airflow’

- Fully seam welded to contain modified atmosphere

- Manual gas control via needle valves & flowmeters (nickel-brass)

- Corrosion-resistant stainless steel interior with perforated non-tip shelves & runners

- Stainless steel pipe-work, nickel brass flow-meter & solenoid valves

- Single side hinged door, with metal heat seal & rubber gas tight seal, closed using non-slam handle

- Hard-wearing, zinc coated & stoved epoxy polyester-coated exterior

- Gas inlet connection: bulkhead compression fitting to suit 10 mm outside diameter tube (maximum inlet pressure = 2 bar)

- Door switch

Options (SPECIFY THESE AT THE TIME OF ORDER)

- A range of sophisticated digital controllers, multi-segment programmers and data loggers is available. These can be fitted with RS232, RS485 or Ethernet communications – more information

- Automatic gas control (requires a EPC3016P1, CC-T1, EPC3008P10 or Nanodac series programmable controller)

- Stainless steel flow meter & solenoid valves instead of nickel brass

- Fixed or castor-mounted floor stands

- Flow failure alarm

- Oxygen sensor fitted to the gas outlet to monitor oxygen level, displayed as ppm (parts per million) or percentage. Only available for use with nanodac instruments