Compression mounting compounds utilize heat and pressure to encapsulate a specimen. Buehler’s compression mounting media includes resins, phenolic powder, compression mounting powder and pre-molds that minimize shrinkage while protecting and preserving sample edges during the preparation process.

The choice of a compression mounting media compound depends on the goals of the lab and requirements of final analysis. Many different powders and pre-molds are available to meet the wide variety of needs including colored general purpose phenolic powder, hard mineral filled compounds, clear thermoplastic compounds and conductive compounds for SEM analysis.

Wide Portfolio for Every Application:

- The choice of a mounting compound depends on the goals of the lab and requirements of final analysis. Many different compounds are available to meet the wide variety of needs including colored general purpose phenolic, hard mineral filled compounds, clear thermoplastic compounds and conductive compounds for SEM analysis.

Excellent Edge Retention for Optimal Preparation:

- EpoMet offers excellent edge retention with a high hardness making it ideal for processing very hard materials. The fine particle size of EpoMet F is great for intricate structures and penetration while the granular size of EpoMet G is easier and cleaner to use.

Quick Cycle Set-Up with No Mess:

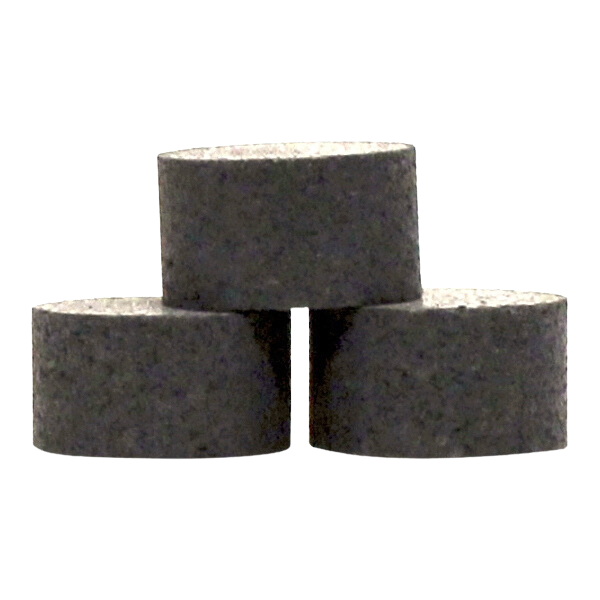

- Eliminate measuring from the mounting process with PhenoCure Pre-Molds. Simply place a pre-measured puck of pressed phenolic powder into the mounting chamber and the cycle is ready to begin. Save time and maximize cleanliness by eliminating any measuring and pouring of powder.