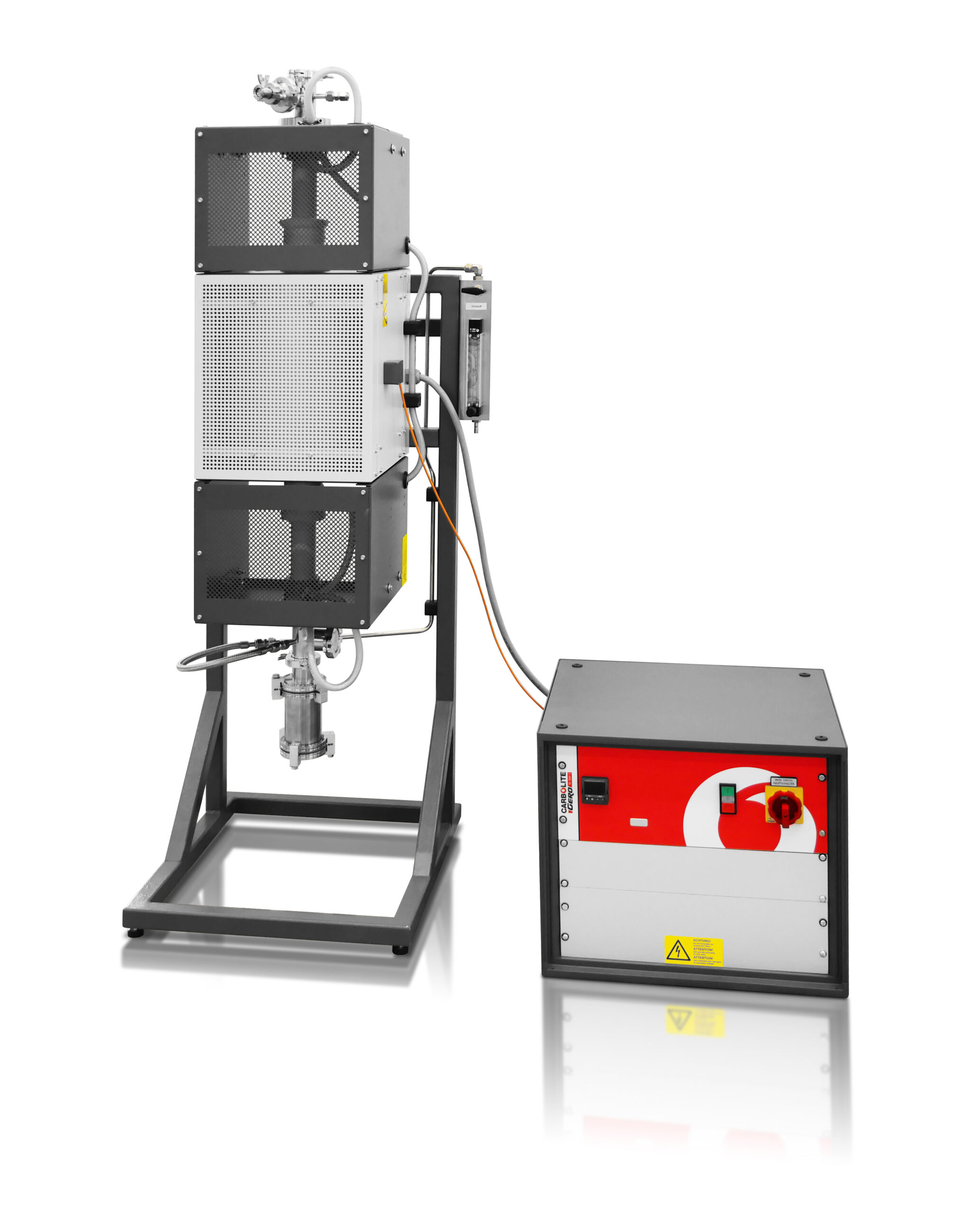

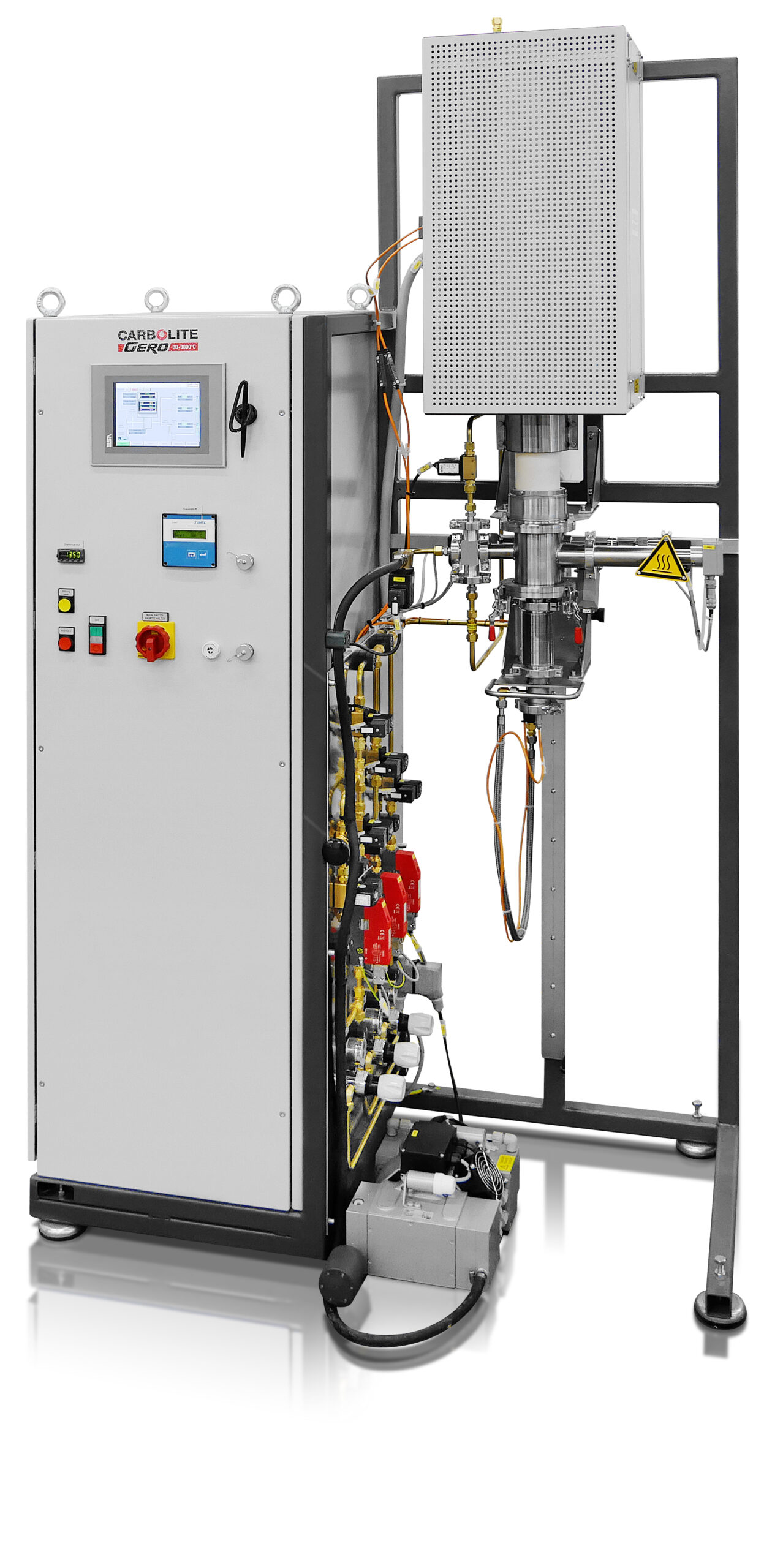

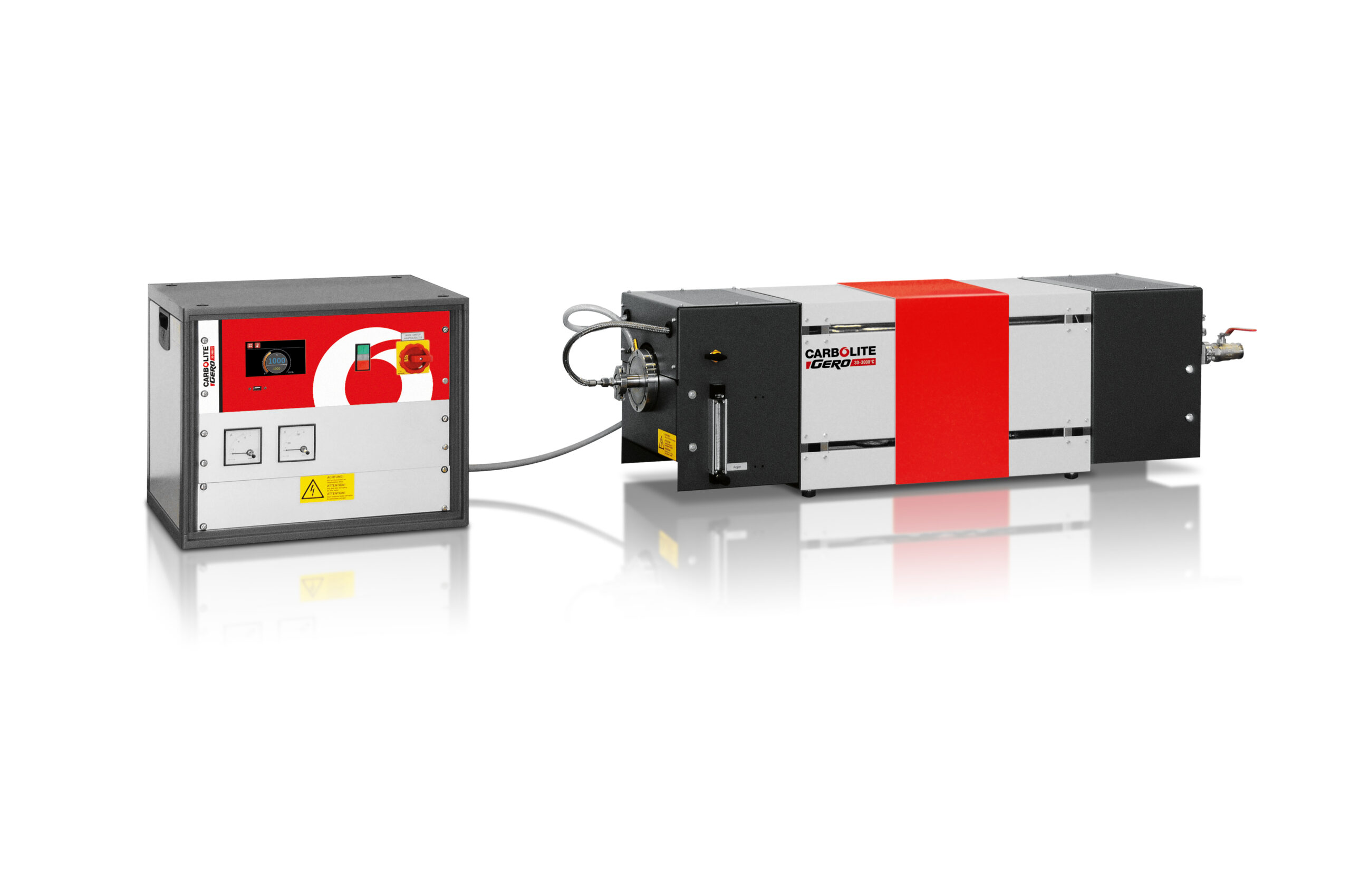

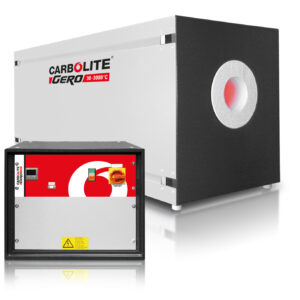

The FHA, single zone, and FHC, 3-zone tube furnaces can be used either vertically or horizontally and have a maximum operating temperature of 1350 °C.

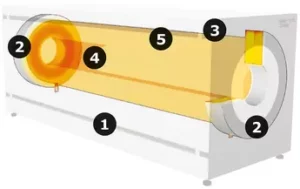

The extensive F range of tube furnaces offers a wide range of accessories. The furnaces comprise ceramic fibre modules with a high-quality 5 mm APM wire heating element mounted in the insulation, held in position by a ceramic holding ridge. The low thermal mass ceramic fibre insulation ensures low energy consumption and allows fast heating rates. The control thermocouple is a high-grade type S thermocouple. Additionally, the tube furnace has up to 8 heating zones for the most precise temperature control and uniformity.

STANDARD FEATURES

- 1350 °C maximum operating temperature

- Programmable temperature controller with 24 segments: FHA fitted with EPC3016P1, FHC fitted with CC-T1

- Over-temperature protection

- Accepts work tubes with outer diameters up to 110 mm

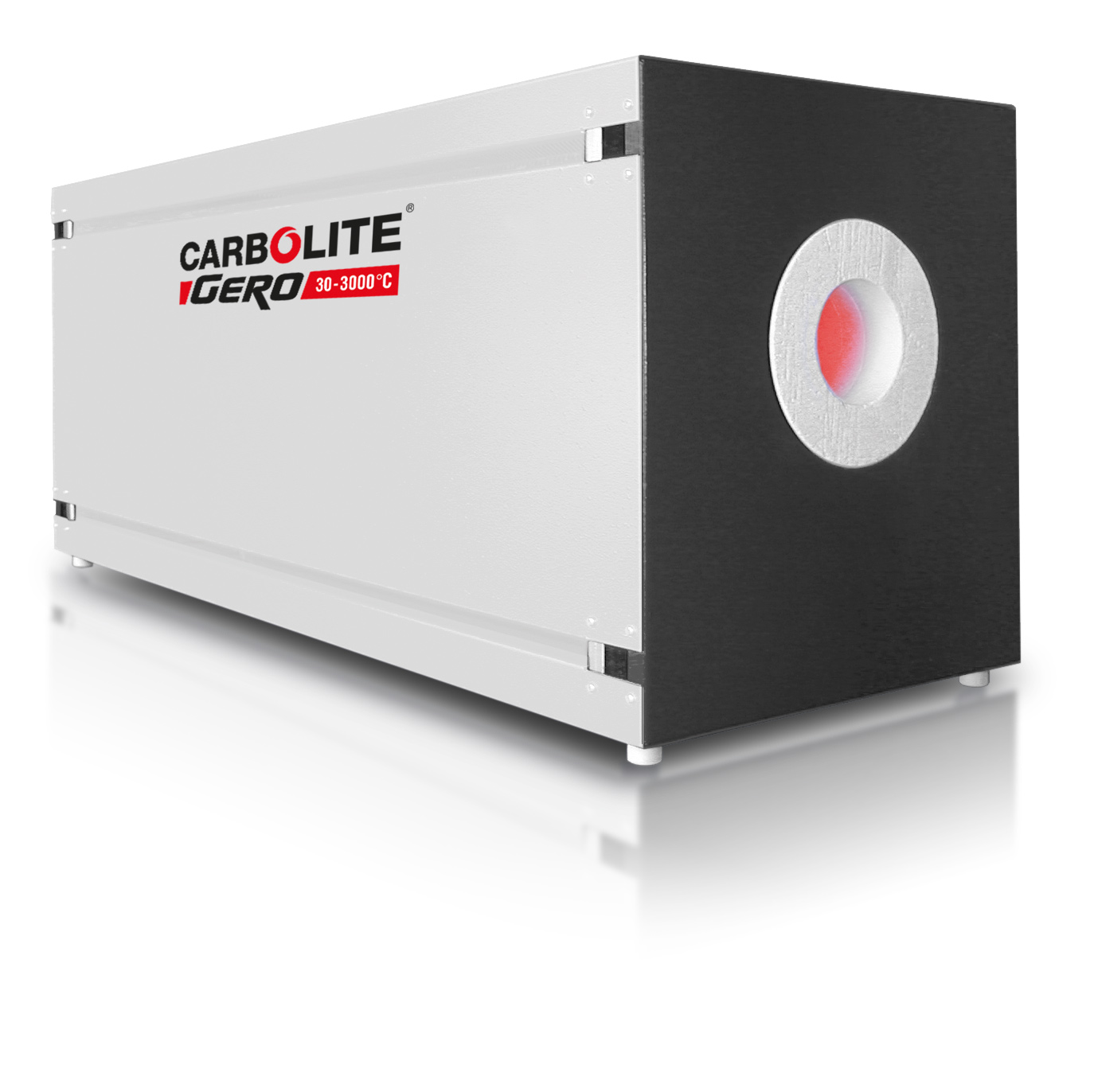

- Heated lengths of 200, 500, 750, 1000 or 1250 mm

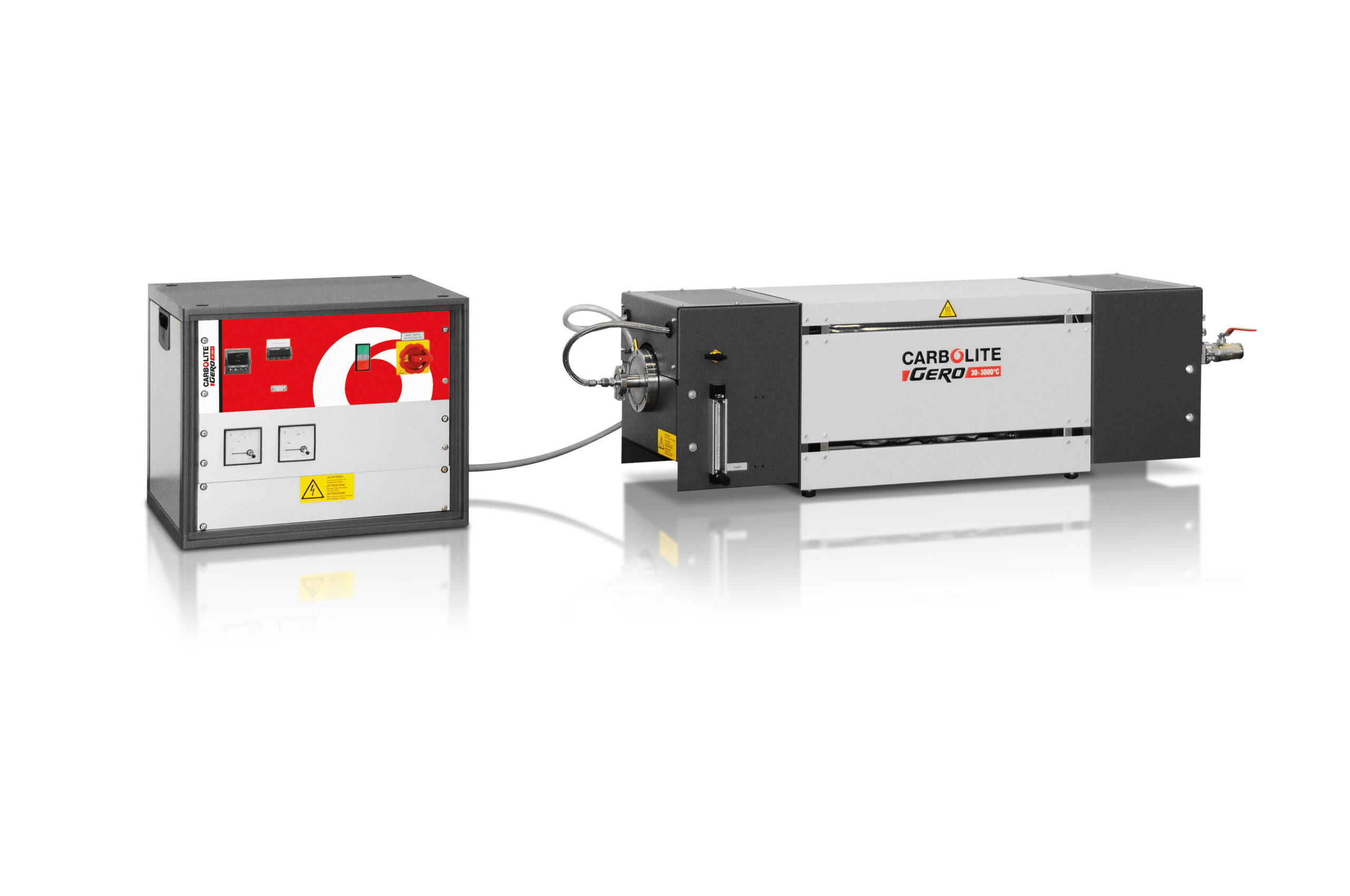

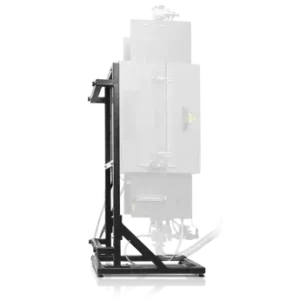

- Use in a horizontal or vertical orientation

- Exceptional lifetime and temperature stability

- High-grade type S thermocouple

- Low thermal mass ceramic fibre insulation

- High-quality 5 mm APM wire as a heating element

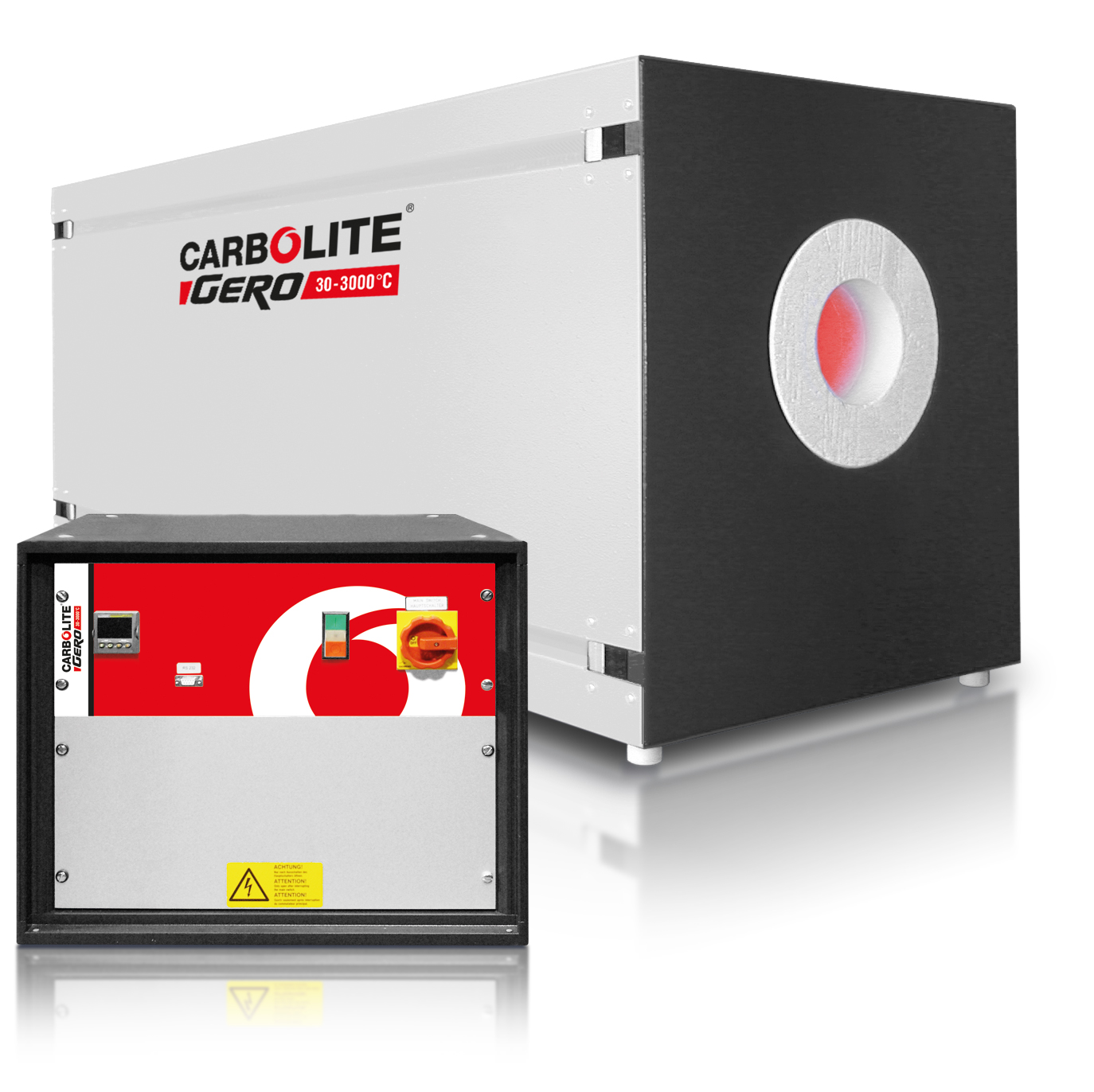

- The furnace is fitted with a separate control box with a 3 m cable, plug and socket

- Ethernet communications