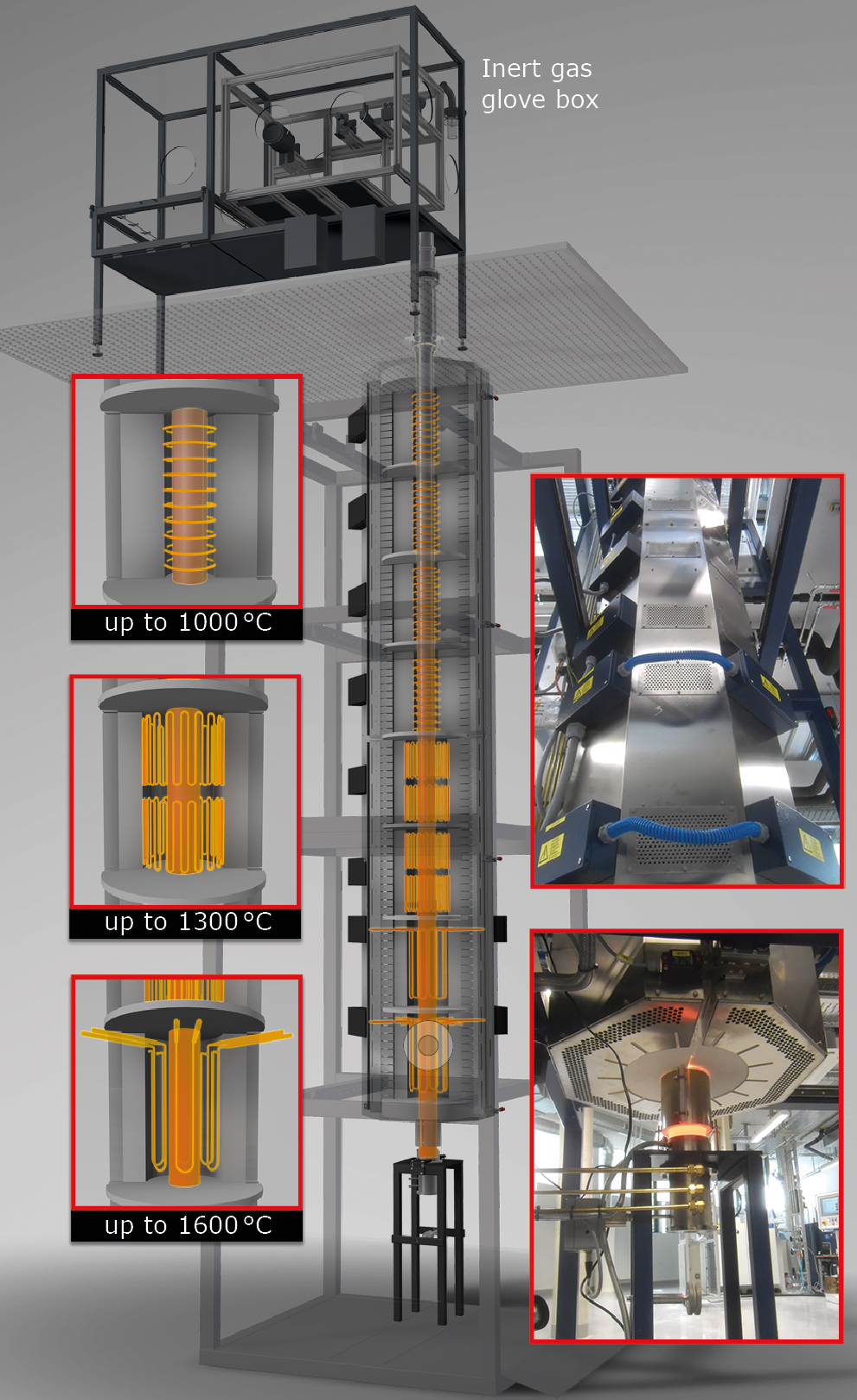

The HTRV-A split tube furnaces have a maximum operating temperature of 1700 °C.

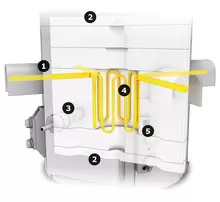

The split heating module allows easy positioning of the work tube or around reactors with fixed-end flanges. The split design may also allow faster cooling of samples. The control thermocouple is fitted in the centre of the heating zone. Cooling channels are engineered into the housing to aid with convection cooling of the outer case.

The two furnace chamber halves comprise high-grade insulation plates with vertically hanging MoSi2 heating elements. A safety switch protects the operator by switching off the heating elements once the furnace is opened.

The tube furnace is supplied without a stand, allowing customers to build them into their equipment. Optional ‘L’ stands are available, making the furnaces self-supporting.

APPLICATION EXAMPLES

annealing, carbonization, crystal growth, debinding, degassing, drying, hardening, metal injection moulding (MIM), pyrolyzes, rapid prototyping, sintering, sublimation, synthesis, tempering

STANDARD FEATURES

- 1600 and 1700 °C maximum operating temperatures

- Programmable EPC3016P1 controller

- Over-temperature protection

- Designed for vertical use

- Accepts work tubes with outer diameters up to 100 mm for use with modified atmosphere

- Heated lengths of 120, 250, 500 or 700 mm

- High-grade type B thermocouple

- Low thermal mass ceramic fibre insulation

- Vertically hanging high-quality MoSi2 heating elements

- Supplied with separate control box and 3 m cable, plug and socket

- Ethernet communications