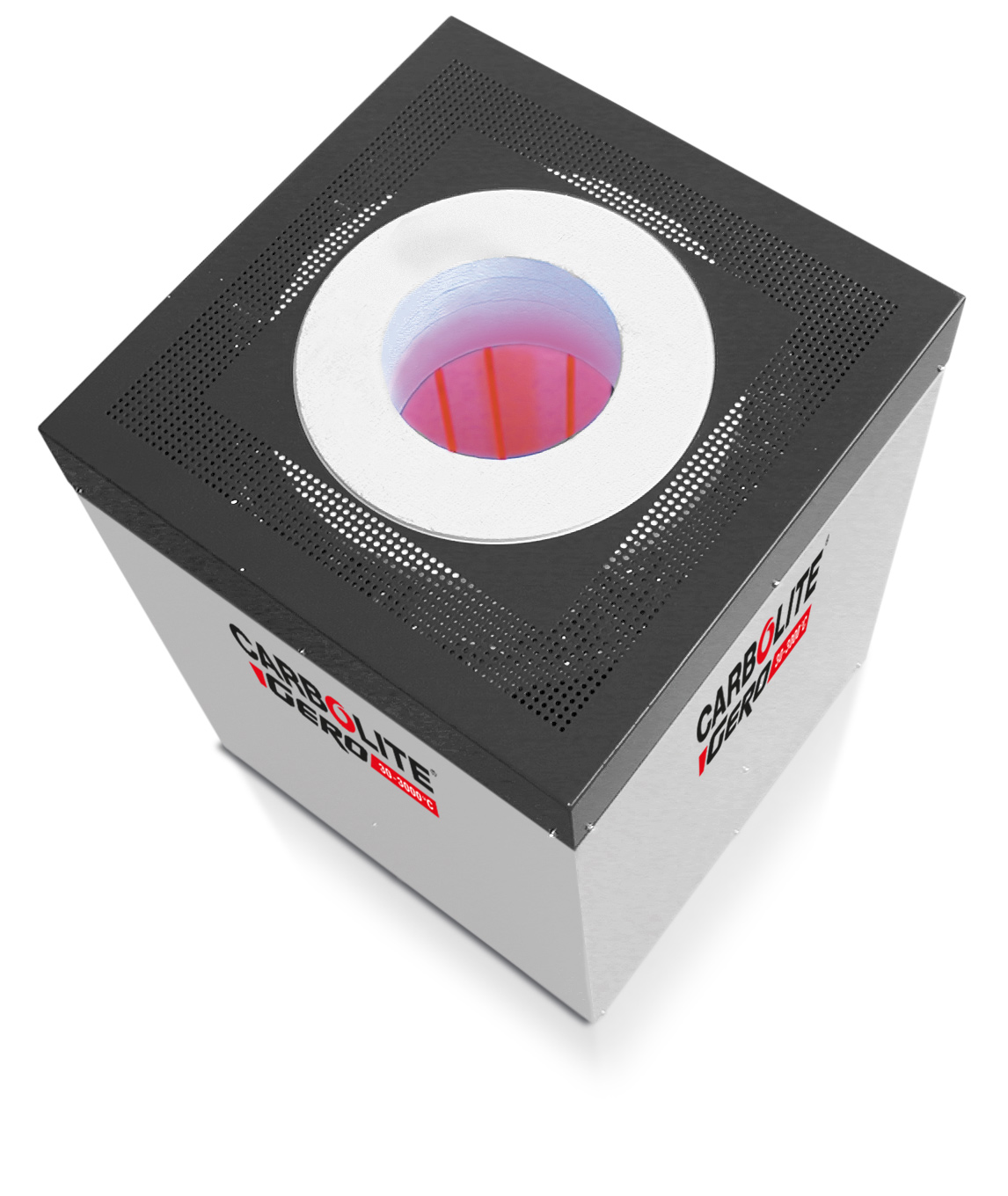

The HTRV high temperature tube furnaces are designed for vertical orientation and operation up to 1800 °C.

The high-grade insulation material consisting of fibre plates provides low energy consumption and high heating rates due to its low thermal conductivity. The insulation and the molybdenum disilicide (MoSi2) heating elements are installed in a rectangular housing. The heating elements hang vertically and can be easily replaced. At higher temperatures and in the presence of oxygen, MoSi2 develops an oxide layer which protects the heating elements against further thermal or chemical corrosion.

With its wide range of accessories, the comprehensive HTRV tube furnace range provides complete system solutions for ambitious thermal treatment at high temperatures.

Furnaces are supplied without a stand, allowing customers to build them into equipment. Optional ‘L’ stands are available, allowing the furnaces to be self-supporting.

APPLICATION EXAMPLES

annealing, carbonisation, crystal growth, debinding, degassing, drying, hardening, metal injection moulding (MIM), pyrolyzes, rapid prototyping, sintering, sublimation, synthesis, tempering

STANDARD FEATURES

- 1800 °C maximum operating temperature

- Programmable EPC3016P1 controller

- Over-temperature protection

- Optimized for vertical usage

- Accepts work tubes with outer diameters up to 100 mm for use with modified atmosphere

- Accepts work tubes with outer diameters up to 200 mm for use in air

- Heated lengths of 100, 250 or 500 mm

- High-grade type B thermocouple

- Low thermal mass ceramic fibre insulation

- Vertically hanging, high-quality MoSi2 heating elements

- Rectangular housing with holes for convection cooling

- The furnace comes with a separate control box with a 3 m cable, plug and socket

- Ethernet communications

View inside the HTRV high temperature tube furnace

View inside the HTRV high temperature tube furnace