DM6 M LIBS Microscope for Rapid, Precise Material Analysis

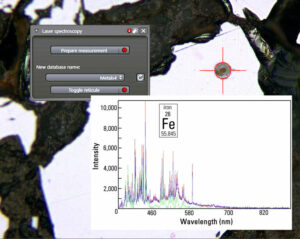

With the DM6 M LIBS, you can quickly and accurately determine the chemical composition of the microstructure visible in the microscope image using integrated laser spectroscopy. Select the microstructure you want to analyze and initiate the LIBS analysis with a single click. Results will be available in just one second.

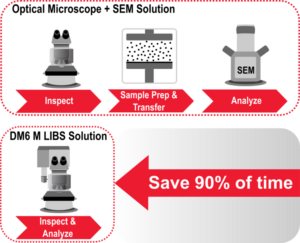

Your advantages

- Save 90% time for chemical analysis compared to typical methods involving electron microscopy* and

- Quick, confident decision-making based on reliable information about the visual and chemical material.

*proof available upon request

Visual & chemical material inspection 2-in-1

- 2 systems in 1 for visual & chemical analysis

- 1 second to a chemical fingerprint

- 0 sample preparation

Great! Click once to examine what you see through the eyepieces or camera for quick and easy identification and interpretation. The operator doesn’t need any extra expertise.

No SEM sample preparation required

No SEM sample preparation required

Why does materials analysis with the DM6 M LIBS solution take 90% less time? Because it requires:

- no sample preparation nor transfer;

- no system adjustment; and

- no relocating the region of interest (ROI).

Reduce the workflow to just one step and focus on results. For further details on composition analysis using the DM6 M LIBS, we recommend referring to Leica’s application note.

Decide rapidly what to do

With advanced tools for analyzing the microstructure composition of a sample, you can obtain all the necessary information within a second to make informed decisions. In over 90% of cases, the data obtained is enough for users to decide on further actions to take confidently, such as conducting a detailed analysis with SEM to identify the source of contamination*.

*based on user feedback

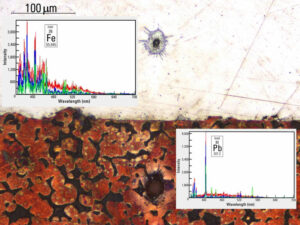

Cleanliness Analysis of Components

Cleanliness Analysis of Components

With the DM6 M LIBS 2-in-1 system and Cleanliness Expert analysis software, you can efficiently conduct visual and chemical inspections on filter samples using a single instrument and workflow. This helps identify the source of contamination quickly and accurately.

Make confident decisions

Gathering information on the particle composition and structure in a timely manner allows for quicker and more confident decision-making during analysis.

Evaluation of Microstructure Composition

Evaluation of Microstructure Composition

With the DM6 M LIBS 2-in-1 solution, you can easily analyze the structural and elemental/chemical composition of various materials such as minerals, alloys, ceramics, and more. This single instrument eliminates the need for sample preparation and transfer between multiple devices, streamlining the analysis process.

Minimizing labour-intensive sample preparation

You can save time and money by minimizing labour-intensive sample preparation and costly SEM/EDS analysis.

Depth Profile and Layer Analysis of Materials

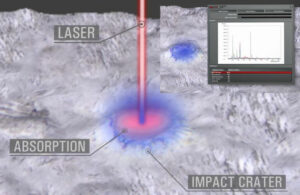

The ablation principle of LIBS can be exploited for micro-drilling into materials.

Applications of µ-drilling are such things as:

- Depth profiling

- Layer analysis

- Surface cleaning.

Determining whether a material’s composition changes as you go deeper into it can be done through depth profiling. To determine the composition of each layer in a material, layer analysis can be used. Materials with multiple layers, such as painted or multi-coated metals, are examples of such materials. To remove oxides and contamination from the surface, surface cleaning can be utilized.

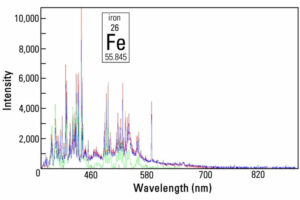

LIBS: Your Chemical Analysis Lab

LIBS: Your Chemical Analysis Lab

With DM6 M LIBS, you can perform qualitative chemical analysis using Laser Induced Breakdown Spectroscopy (LIBS). Simply click a button to trigger the analysis, and a laser will strike the designated area on the sample. This creates a plasma that breaks down, revealing the characteristic light spectrum that displays the elements present in the material. The software then compares this spectrum with a known data set for elements and compounds, allowing it to identify the microstructure composition. If necessary, the data set can be updated with the results of specific materials obtained by the user.

DM6 M LIBS Solution: The Microscope’s Contribution

For a rapid materials analysis workflow with the 2-in-1 solution, microscopy also plays an important role.

The DM6 M compound microscope offers

- Observation with a large objective magnification range from 1.25x to 100x;

- Easy visualization of a material’s fine structure in its true colours with multiple contrast techniques;

- Freedom to make the analysis whenever you want.

Upgrade with LIBS for a 2-in-1 solution

It’s Never Too Late!

Do you already have one of our DM6000 M or DM6 M compound microscopes?

If so, then you can take advantage of the option to retrofit it with a LIBS system – and have a 2-in-1 solution at an advantageous price.

No SEM sample preparation required

No SEM sample preparation required Cleanliness Analysis of Components

Cleanliness Analysis of Components Evaluation of Microstructure Composition

Evaluation of Microstructure Composition LIBS: Your Chemical Analysis Lab

LIBS: Your Chemical Analysis Lab