After more than 20 years of development work, many algorithms, drivers and SDKs have matured and are gradually finding their way into Optp’s plug-ins or customer applications.

Custom software development

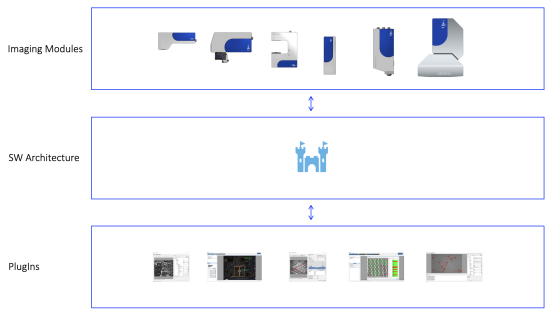

Opto’s software toolbox ‘Fortress’ lets you quickly develop customized software solutions for motion control, light control, autofocus, object tracking, memory management, and big data analysis.

Opto’s software toolbox ‘Fortress’ lets you quickly develop customized software solutions for motion control, light control, autofocus, object tracking, memory management, and big data analysis.

We program with Vision Builder NI, Open CV, and C++ to select your best solution.

For customers who integrate imaging modules into their applications, we support the development of specific GUIs or image-processing solutions.

DATA & Network Management

With Opto’s software framework Fortress, they can easily plan and develop new challenges around image data management and image processing.

With Opto’s software framework Fortress, they can easily plan and develop new challenges around image data management and image processing.

With over 20 years of experience in custom software development, much knowledge has flowed into Opto’s data structure, from which they can now react quickly to the new requirements of our OEM customers.

Also, for our Imaging Modules, new software solutions, so-called plug-ins, are constantly being created in this way. This allows their users to be optimized and opens up new application areas.

Image Analysis

Over the last 40 years, Opto has solved many market-driven challenges that they can easily integrate into our Opto Framework to deliver now “Plug and play” Job Modules for you.

Here are some solutions that can merge easily into new Sensors for you.

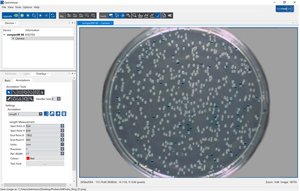

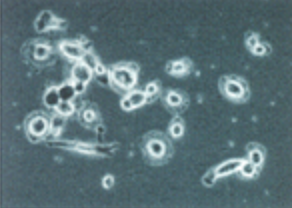

Colony Counting

Counting and Analysing colony growth in Petri dishes request fast Image Acquisition in the highest resolution. Differentiation of colonies in size and gray levels and the differentiation of colony families are other demands besides statistical DATA mining.

Counting and Analysing colony growth in Petri dishes request fast Image Acquisition in the highest resolution. Differentiation of colonies in size and gray levels and the differentiation of colony families are other demands besides statistical DATA mining.

Often mechanical positioning, Autofocus or other Automation has to be applied to the Application.

All can be realized from the Opto Software framework and Imaging Module line.

All out of one Hand.

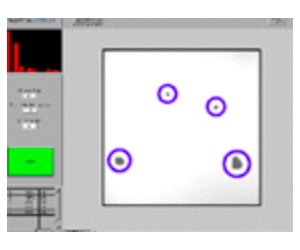

Quality control of pharmaceutical products

During drug development and the production of pharmaceutical products, many quality controls have to take place.

During drug development and the production of pharmaceutical products, many quality controls have to take place.

- Measurement of size and roundness of pills

- Detection and verification of correct colour

- Analysis of the homogeneity of the blister pack

- Classification of defects and anomalies

Detection of impurities in transparent materials

The Quality control of plastic strips used in the fabrication of high-tension electric cable requires:

The Quality control of plastic strips used in the fabrication of high-tension electric cable requires:

- Detecting holes and defects

- Determining position, level and classification of impurities

- Automatic Anomalies detection (Stress, colour,..)

- Statistical analysis of the results, data export

Automated Cell Counting

To analyze cells, it is necessary to control them where they occur—On-Chip Level, Microfluidic Channels, Petri dishes or well plates. We offer the right Image Acquisition Tool and can assist with special Software features for your application.

To analyze cells, it is necessary to control them where they occur—On-Chip Level, Microfluidic Channels, Petri dishes or well plates. We offer the right Image Acquisition Tool and can assist with special Software features for your application.

- Tracking in real-time the morphology and movement of cells

- Classification and Identifying cells by specific Fluorescence Marker

- Automated Counting of cells

- Including cell Analysis into existing Microfluidic setups

Deep Learning & AI

To create an AI solution, it is always essential to work closely with the customer to learn and interpret the products to be analyzed. So working AI solutions are always project-based.

To create an AI solution, it is always essential to work closely with the customer to learn and interpret the products to be analyzed. So working AI solutions are always project-based.

That is why Opto uses existing Software Packages from partner companies in its solino Interface design to set up CNN* and Deep Learning.

Opto wants to cooperate with Companies to make solino their AI tool for

- Predictive Maintenance

- Quality Inspection and Assurance

- Manufacturing Process Automation

Here are some preferred partners:

https://robovision.ai/

https://www.picsellia.com/

* (Convolutional Neural Network)

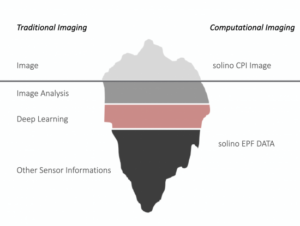

Computational Imaging means extracting additional information out of standard Images.

Computational Imaging needs a deep understanding of the application.

Opto often only assists as an extended development partner.

- solino is Opto’s algorithm for digitizing the Human Perception of products (LINK)

- Super Resolution Effects are possible

- For Computational Microscopy, our Imaging Modules are perfect

Deep Learning & AI Technical Paper

Technical paper: Imaging Modules and AI in Quality Control

Topic: Measurement technology, image processing, CAQ and AI

Author: Markus Riedi, Opto GmbH

Date: 16.03.2020

AI has arrived in society. We are in the middle of the 4th Industrial Revolution and are confronted with fundamental changes in our global economic structure. The ongoing corona crisis will also fundamentally change the way we live and work. The vulnerability of existing processes will perhaps give a huge boost to digitalization and automation and reduce prejudices against new ways. Just like in society, industry should also be able to test this insight in mature new methods. There are already many successful examples in medical technology, drug research and pathology.

In production, every quality assurance officer wants to have a statement on product quality as quickly as possible in order to control his production process. Unfortunately, determining the shape and position, the colour, the tribological properties and all other criteria that make up the function of a product is currently only possible with different measuring instruments, one after the other, and requires a lot of time and money.

What if there were a way to combine all this with a simple, inexpensive, non-contact, fast and environmentally independent analyser? Ingenious, but unrealistic.

Until now.

The idea is to take human evaluation of surfaces as the basis for digitization. Together with the mass available measurement cycles and experience about the product and the information about it known for years, a network is fed and with a solino reflex analysis anomalies are detected to an ideal situation. The resulting data set contains all product-relevant information, which only needs to be analyzed and classified after changes.

This makes it possible to work out the traceability to standards, to generate measurement results or to use the data directly for production control. This would close the control loop for artificial intelligence. Sounds simple, but it is. Nevertheless, it will take some time before we believe these results, because the decisions about good and bad are not traceable according to standards, but have been created in the data room. But also Google bases the decision cat or dog not on image information but on the comparison of its digital twin and is not bad at it. However, Google’s dataset is only a fraction of the one available here, and the tolerances between good and bad are also simpler.

As you can see here in the example, this information can be easily put back into image information and e.g. only the impurities can be read out according to particles or fingerprints. But this only costs computing time and requires a further analysis according to existing image analysis procedures in order to make a decision.

We have started to test deep learning tools and big data algorithms together with the unique Solino technology, which allows us to start the classification not on the basis of images but on data sets containing ALL anomalies of the test object. This enables us to use the solino technology to simulate human perception, rather than using standards to evaluate the quality of a product, as is the case with traditional defect specification solutions.

Opto is on the way to develop new AI modules based on the constantly growing imaging module family, which are equipped with our own solino technology. More than 40 years of experience in the development of cameras with integrated optics and illumination in microscopy and machine vision as well as the long tradition in programming own image processing solutions is the basis of these new modules. Currently more and more machine manufacturers, system integrators and corporations are working on integrating the plug&play OEM solutions around the described imaging modules from Opto into their devices and processes to achieve better results and a reduction of equipment costs in the long term. This disruptive approach may be integrated faster than expected due to the upcoming changes and will become accepted as a replacement for traditional measurement methods. If AI can detect and analyze diseases faster and better, new vaccines can be developed faster and better, why shouldn’t the results speak for themselves and prevail in traditional measurement technology as well?

Opto’s software toolbox ‘Fortress’ lets you quickly develop customized software solutions for motion control, light control, autofocus, object tracking, memory management, and big data analysis.

Opto’s software toolbox ‘Fortress’ lets you quickly develop customized software solutions for motion control, light control, autofocus, object tracking, memory management, and big data analysis. With Opto’s software framework Fortress, they can easily plan and develop new challenges around image data management and image processing.

With Opto’s software framework Fortress, they can easily plan and develop new challenges around image data management and image processing.![]()

Counting and Analysing colony growth in Petri dishes request fast Image Acquisition in the highest resolution. Differentiation of colonies in size and gray levels and the differentiation of colony families are other demands besides statistical DATA mining.

Counting and Analysing colony growth in Petri dishes request fast Image Acquisition in the highest resolution. Differentiation of colonies in size and gray levels and the differentiation of colony families are other demands besides statistical DATA mining. During drug development and the production of pharmaceutical products, many quality controls have to take place.

During drug development and the production of pharmaceutical products, many quality controls have to take place. The Quality control of plastic strips used in the fabrication of high-tension electric cable requires:

The Quality control of plastic strips used in the fabrication of high-tension electric cable requires: To analyze cells, it is necessary to control them where they occur—On-Chip Level, Microfluidic Channels, Petri dishes or well plates. We offer the right Image Acquisition Tool and can assist with special Software features for your application.

To analyze cells, it is necessary to control them where they occur—On-Chip Level, Microfluidic Channels, Petri dishes or well plates. We offer the right Image Acquisition Tool and can assist with special Software features for your application. To create an AI solution, it is always essential to work closely with the customer to learn and interpret the products to be analyzed. So working AI solutions are always project-based.

To create an AI solution, it is always essential to work closely with the customer to learn and interpret the products to be analyzed. So working AI solutions are always project-based.