The Opto Solino Imaging Module 10×12 is a complete computational imaging vision sensor that uses Opto’s proprietary solino® technology to display object anomalies as an image for further digital or statistical processing.

The Opto Solino Imaging Module 10×12 is a complete computational imaging vision sensor that uses Opto’s proprietary solino® technology to display object anomalies as an image for further digital or statistical processing.

With a field of view of 10mm x 12mm, it is ideally suited for the following:

- Forensic examinations

- Quality assurance on scattering surfaces

- Anomaly detector for 100% inspection

Ask for a demo or send us your sample.

AI ready sensor

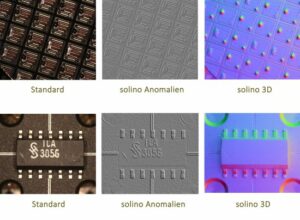

Solino digitizes the visual appearance of objects

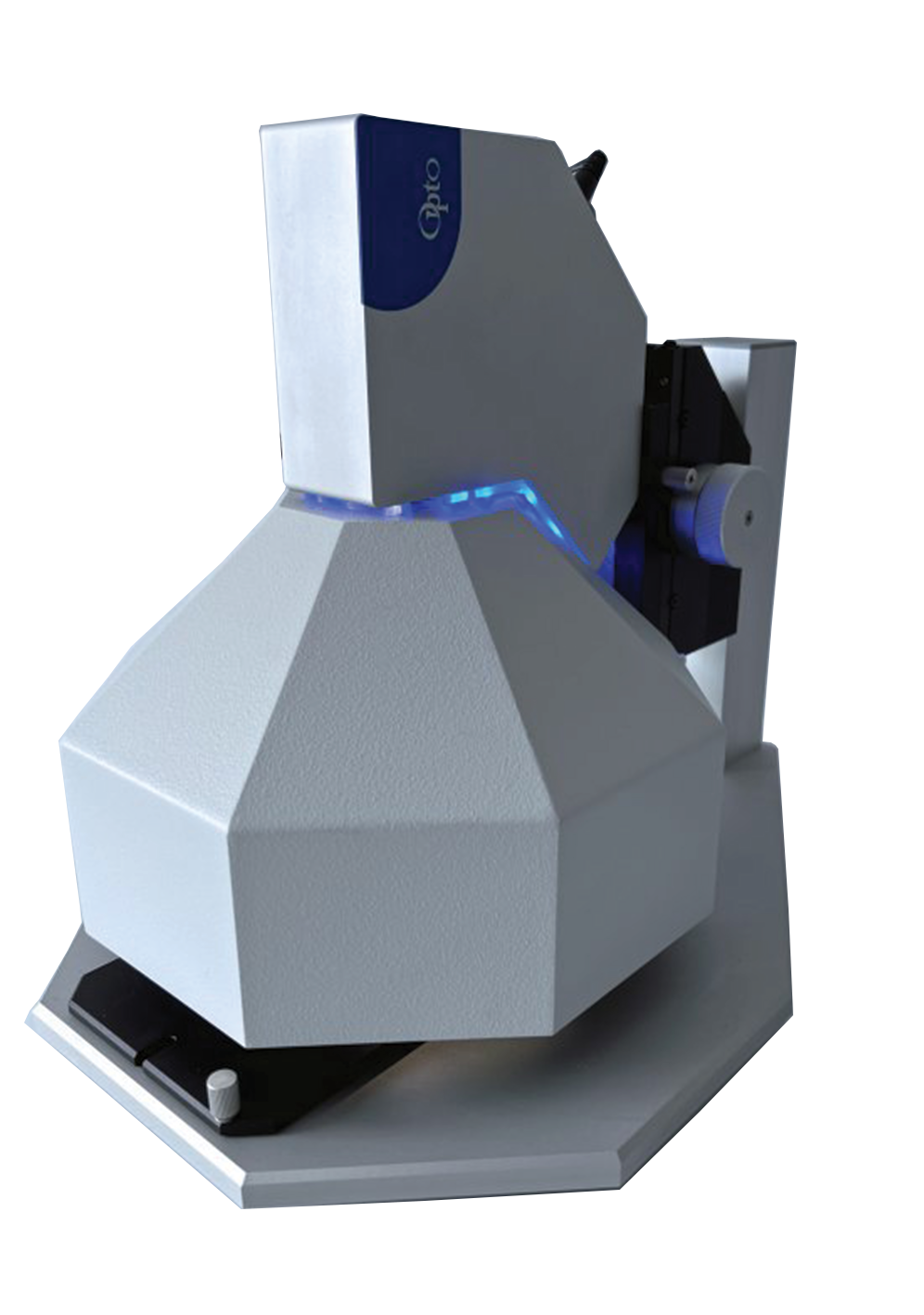

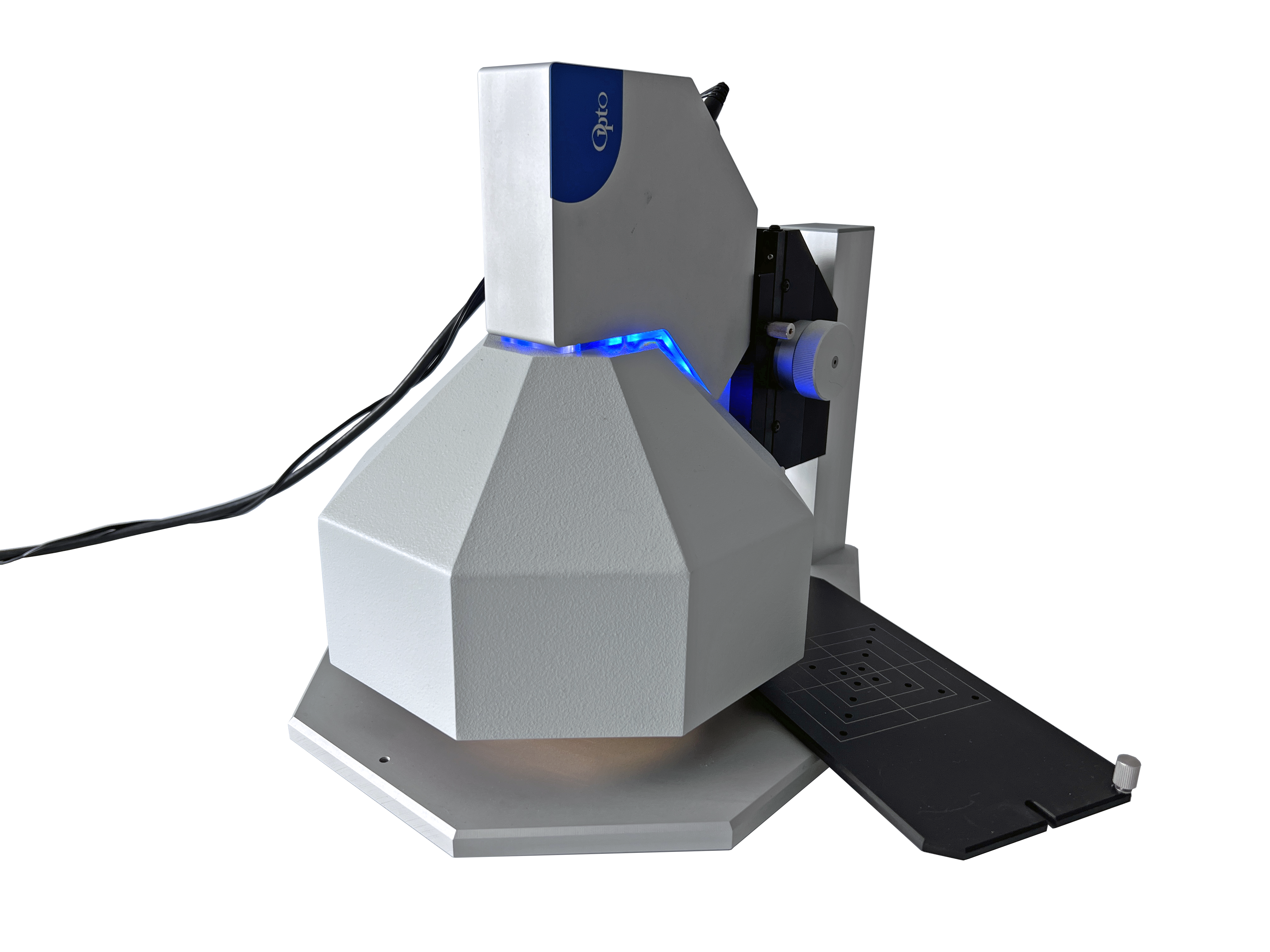

- Powerful Plug-and-Play Imaging Module

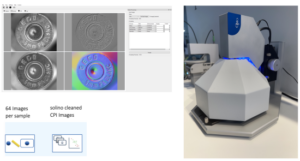

- Photometric Stereo Imaging acquisition software included

- Integrated 64-LED mesh dome illumination

- Redefines textural surface standards

- Robust design with multiple mounting options

Benefits

- Detects all surface characteristics and anomalies

- Detection of contamination on PCB ́s surface

- Detection of Roughness, Reflectivity, Inclination

- Eliminates reflections on metallic surfaces

- Code detection on tires and O-rings

Applications

- Predictive maintenance

- Quality inspection and assurance

- Manufacturing process automation

- Easy inspection of bubbles, staining, fingerprints, dents, cracks, etc.

Solino 10×12 as a stand-alone and as a process sensor

The IM•solino 10×12 sensor for anomaly detection can be used as a laboratory system to develop its quality guidelines for product classification. Accordingly, it is also typically used as a process sensor in manufacturing.

As with all Opto Imaging modules, the same applies here: The image counts. Plug & play, repeatable, reliable. The difference is the image information. Through specific filter algorithms, unimportant information can be suppressed.

Employing 64LED dome mesh illumination and applied reflex analysis, a wide variety of product characteristics can be comprehensively digitized. We are happy to assist you in the development of solino®-based AI solutions.