Solino Technology uses computational methods to add immediate value to your process and product Quality Control. Opto provides tools to build a sustainable visual inspection strategy. Solino Technology is based on specially developed algorithms that analyze the scattering pulse of incident light on surfaces and extract anomalies. These, in turn, are displayed again as individual images which show the defect or change as a contrast or colour change.

Solino Technology cleans the image information of the images captured via the solino 10×12 Imaging Module, with its 64LED mesh dome illumination, and brings out faint object anomalies as dominant image information.

We consider surface appearance as a combination of

light and three production parameters such as :

- Material

- Shape

- Hue

The visual image information collected is the perceived colour due to the interaction of light and surface. LED illumination is a known parameter, similar to the camera sensor.

Solino® defines relative quality rules that depend on the hardware but are based on human perception. The goal of solino® is an automated inspection system that digitizes visual perception.

Solino® digitizes the visual appearance of objects

Solino technology works towards a digital transformation and digitizes the visual appearance of objects.

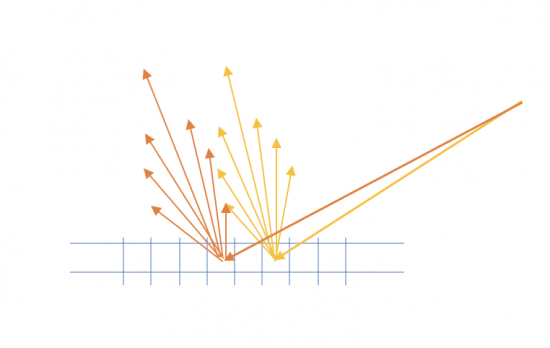

The visual appearance of objects is given by how they reflect and transmit light.

The colour of objects is determined by the parts of the (incident white) light spectrum that is reflected or transmitted without being absorbed.

Appearance attributes are based on the directional distribution of reflected light (BRDF – Bidirectional reflectance distribution function), the computational decomposed measurement by solino®. Appearance could be described by attributes like matte versus glossy.

Appearance attributes are based on the directional distribution of reflected light (BRDF – Bidirectional reflectance distribution function), the computational decomposed measurement by solino®. Appearance could be described by attributes like matte versus glossy.

Matte

- Does not reflect light and has less shiny

- Softer images and colours with a greater tonal range

- Soft and smooth to the touch

Glossy

- Highly reflective for a bright shine

- More vibrant, saturated colours and highlighted details

- A shiny, wet look that makes for a striking finish

solino® analyses the stray response

solino® is a disruptive Technology that can add significant value to the qualification of any quality control procedure

solino® is a way of interpreting image data by analyzing its stray response instead of the image itself.

The stray behaviour is based on the surface structure and is the ideal digital footprint of a product. All relevant object information is stored in coded form in a solino™ data set:

The stray behaviour is based on the surface structure and is the ideal digital footprint of a product. All relevant object information is stored in coded form in a solino™ data set:

- Geometrical data

- Colour

- Waviness

- Super-resolution effect

- Anomalies