STANDARD FEATURES

- 1300 °C, 1600 °C, 1700 °C & 1800 °C maximum operating temperatures

- Programmable EPC3016P1 controller

- From 80 to 514 litre capacities

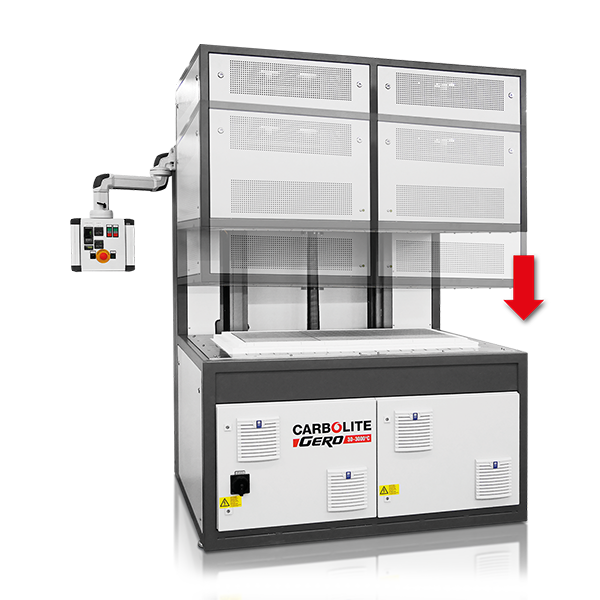

- HB = top hat. HB-BL = bottom loading

- FeCrAl wire heating elements for 1300 °C models

- High quality molybdenum disilicide heating elements for higher temperatures

- Energy efficient low thermal mass insulation

- Over-temperature protection

- Ethernet communications

CONFIGURATIONS

OPTIONS (SPECIFY THESE AT TIME OF ORDER

- A range of sophisticated digital controllers, multisegment programmers and data loggers with digital communication options is available

- Gas inlet for operation under modified atmosphere (not gas tight)

- Preheated air blower up to 650°C

- Active propane gas after burner or catalytic oxidiser for safe combustion of debinding applications

- Reinforced base plate for a surface load of 500 kg/m2 instead of 250 kg/m2

- Bottom heater for improved temperature uniformity (this option cannot be combined with the reinforced base)

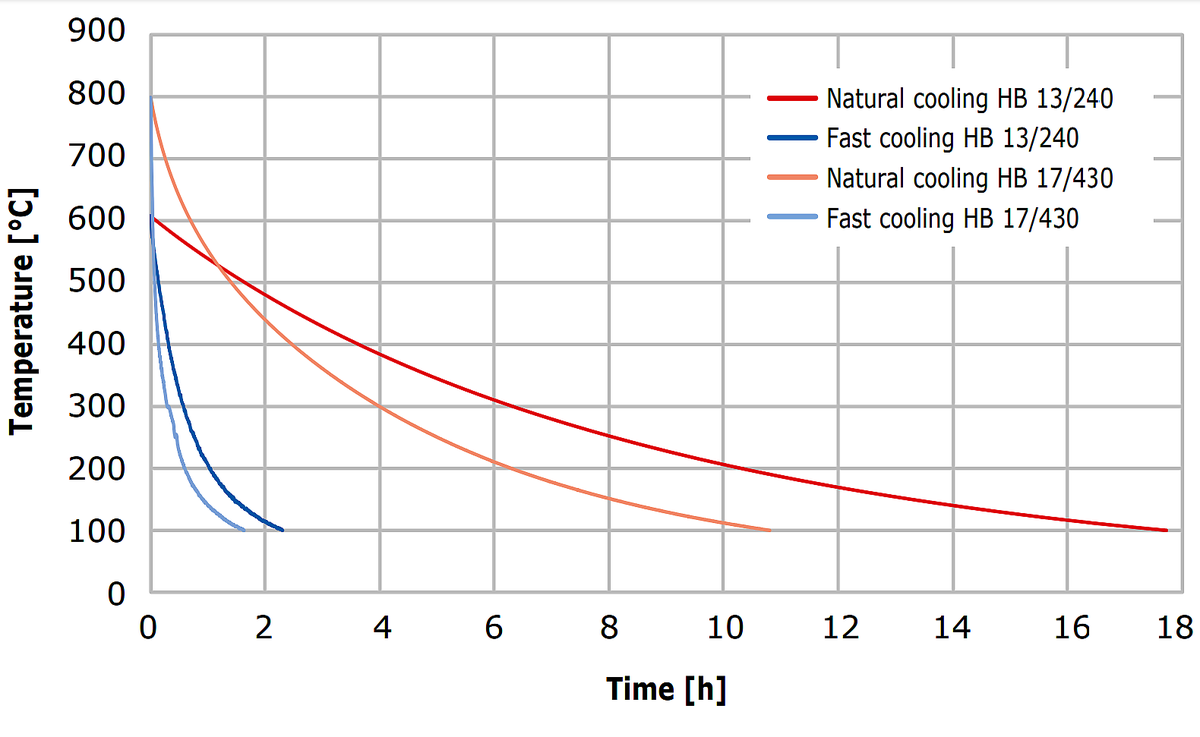

- Fast cooling options

APPLICATION EXAMPLES

Annealing, ceramic injection moulding (CIM), debinding, debinding in air, degassing, drying, sintering, sintering in air, sublimation, synthesis, tempering

TECHNICAL DETAILS

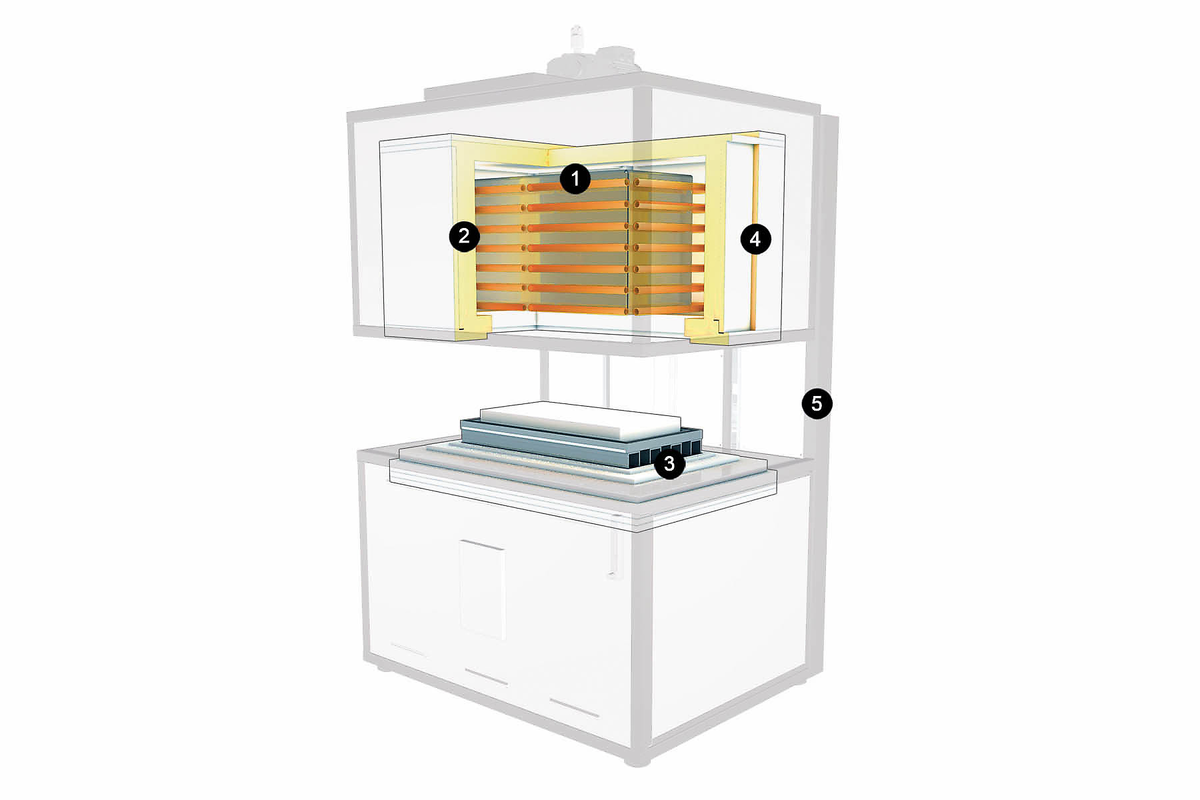

- FeCrAl heating elements up to 1300 °C

- Low thermal mass insulation

- Top hat: steady hearth; Bottom loading: movable hearth

- Top hat: movable hood; Bottom loading: steady hood

- Frame