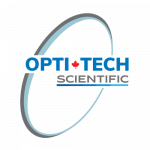

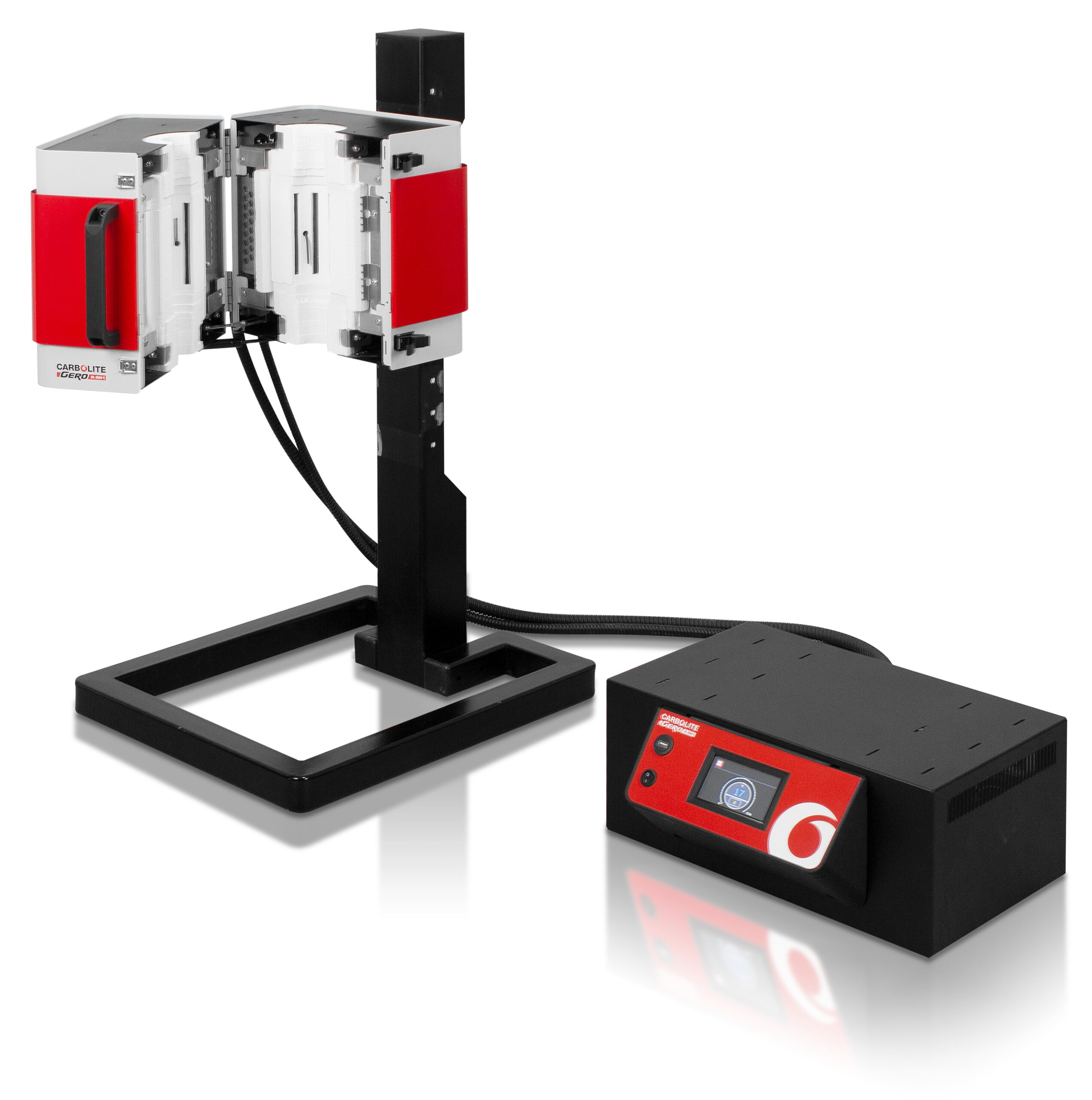

Carbolite Gero’s versatile new TS split tube furnace range incorporates high-quality heating elements and innovative thermal insulation design to achieve first-class performance while maintaining reduced case temperatures and power consumption.

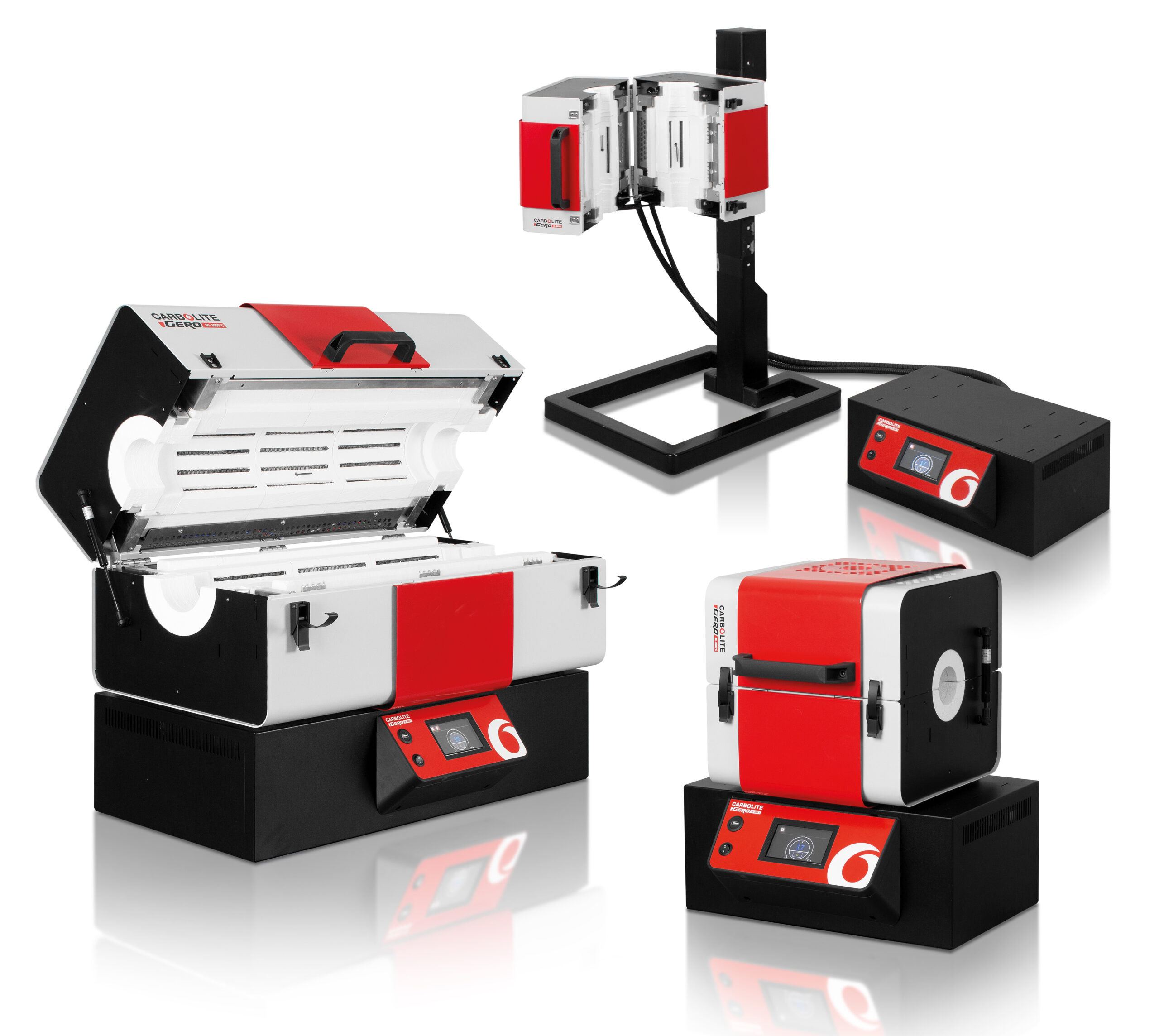

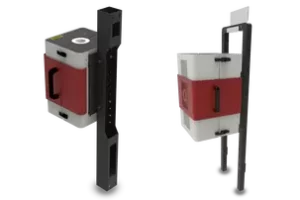

The TS furnace body is split into two halves and hinged at the rear; pneumatic dampening struts at either end provide a smooth opening action. The ability to open the furnace makes it easier for operators to exchange work tubes or insert vessels, such as reactors, with end flanges that make them difficult to insert into a non-split furnace.

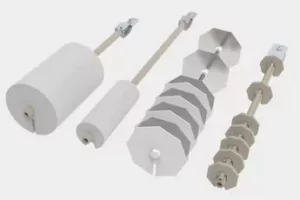

The TS split tube furnace range has been designed with flexibility in mind. Accessory work tubes and tube adapters allow a single furnace to accommodate a variety of tube diameters, whilst the work tubes themselves can easily be exchanged to meet a process’s different physical or chemical requirements. Optional work tube packages enable users to equip the TS for operation under a vacuum or modified atmosphere.

Carbolite Gero’s new tube furnace range is at the pinnacle of furnace design. The culmination of over 80 years of experience in thermal engineering, combining the latest technological developments with solid construction, high-quality components and a sleek, modern aesthetic.

HIGH-QUALITY HEATING ELEMENTS

- Excellent temperature uniformity

- Fast heat-up and cool-down rates

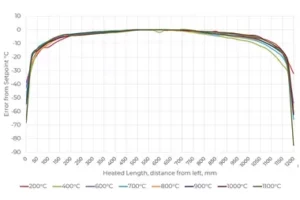

- Unsurpassed temperature uniformity along the entire heated length

HIGH-QUALITY THERMAL INSULATION

- Low energy consumption

- Low external case temperature

- Designed for longevity

EXCELLENT TEMPERATURE UNIFORMITY: HOT STUFF!

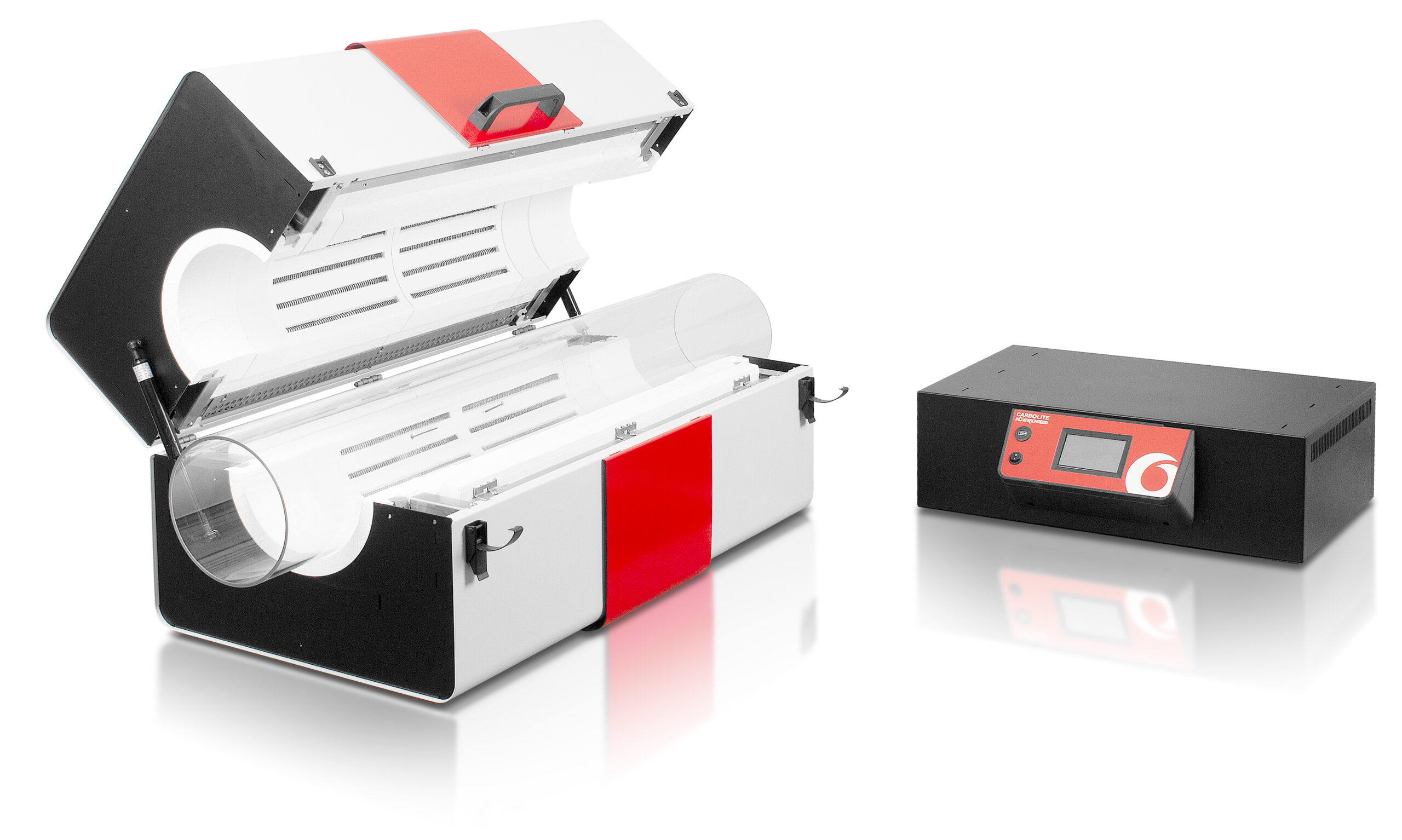

Carbolite Gero’s tube furnace range boasts various technical features to maximize the heated length of the furnace, ensuring that as much of the work tube as possible is heated to the setpoint temperature. These include heating elements evenly distributed around the work tube and low thermal mass insulation.

To achieve the longest possible heated length, our 3-zone models feature increased power boosting at the ends of the furnace, ensuring the best possible temperature uniformity throughout the working volume.

Combining your furnace with work tube packages that include thermal insulation plugs or radiation shields helps prevent thermal losses from the ends of the work tube. Carbolite Gero is

hard to beat regarding the uniform distribution of heat!

TEMPERATURE CONTROL & COMMUNICATIONS

TS split tube furnaces are equipped with ethernet communications and a programmable controller with 24 segments as standard:

TS split tube furnaces are equipped with ethernet communications and a programmable controller with 24 segments as standard:

- Single zone furnaces fitted with Carbolite Gero EPC3016P1 controller

- Three-zone furnaces fitted with Carbolite Gero CC-T1 touch-screen controller

OPTIONS

- Over-temperature protection (recommended to protect valuable contents and for unattended operation)

- A range of sophisticated digital controllers, multi-segment programmers and data loggers are available. These can be fitted with RS232, RS485 or Ethernet communications—more information.

RAPID HEATING RATES

Carbolite Gero tube furnaces have high-quality heating elements to achieve fast heat-up rates. Optimize your lab time by speeding up your heat treatment processes!

Precise temperature measurements are carried out in the Carbolite Gero testing laboratory and are available for all models.

LOW ENERGY CONSUMPTION

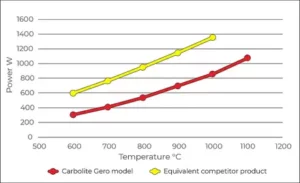

Carbolite Gero’s new tube furnaces are very energy-efficient. Their high-quality thermal insulation is designed for longevity, low case temperature and outstandingly low energy consumption.

Using a Carbolite Gero tube furnace reduces your energy cost and carbon footprint.

UP TO 50% LESS ENERGY IS REQUIRED! COMPARISON WITH EQUIVALENT COMPETITOR PRODUCT

MODIFIED ATMOSPHERE & VACUUM EQUIPMENT

Carbolite Gero tube furnaces may have many options to accommodate modified atmosphere and/or vacuum applications.

OPTIONS

- A range of additional work tubes, end seals and complete work tube packages

- Vacuum packages with a choice of rotary vane pumps or turbomolecular pumps

- Inert gas package modules allow for the use of up to 3 non-reactive gases (available with either manual or automatic control)

- Laboratory Gas Safety System for safe use with hydrogen above 750 °C

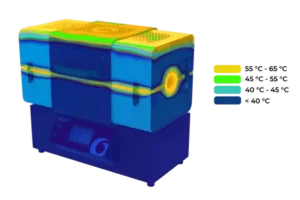

THAT’S COOL! LOW CASE TEMPERATURE

Carbolite Gero tube furnaces are designed with user safety in mind.

Carbolite Gero tube furnaces are designed with user safety in mind.

The robust construction and high-quality thermal insulation ensure that external case temperatures are much lower than in other models.

Not only does this help mitigate the risk of injury to the operator, but the reduction in the heat escaping the furnace ensures a comfortable working environment and means that less energy is wasted during use. Carbolite Gero can help you keep a cool head when the heat is on!