Today, we dive into the fascinating world of metallography! This scientific discipline has completely transformed our understanding of engineering materials and their properties. Through the analysis of their chemical and atomic structures, as well as the spatial distribution of grains, components, inclusions, and phases, we gain top insights into the relationship between microstructure and physical properties. In this general guide, we’ll explore the fundamentals, the cutting-edge techniques used in its practice, and its wide-ranging applications across numerous industries.

Understanding Metallography

This fascinating discipline has its roots in the pioneering work of the brilliant 19th-century scientist Henry Clifton Sorby. His groundbreaking research in Sheffield, UK, revealed the close relationship between microscopic structure and the physical properties of today’s modern iron and steel. Sorby’s visionary approach paved the way for the development and expansion of metallography, a vital discipline that continues to shape our world.

With a deep understanding of the microstructure, metallographers can unlock insights into properties like tensile strength, ductility, and hardness. This knowledge is essential for developing, manufacturing, and ensuring the quality of materials across various industries we see daily.

Techniques

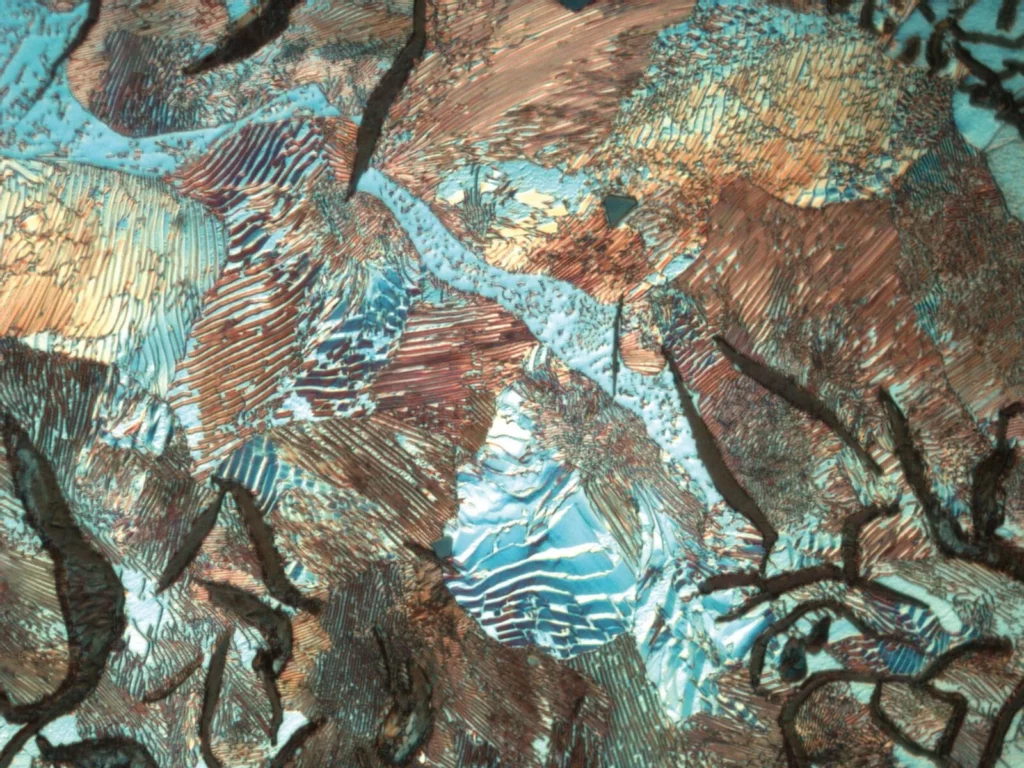

Metallographers use an arsenal of techniques to evaluate and uncover the hidden microstructural features of metals. The most popular approach is incident light microscopy in brightfield mode, which offers an up-close and personal view of the microstructure. However, methods such as darkfield or differential interference contrast (DIC) microscopy and colour (tint) etching are becoming more common in metallographic applications.

Metallographers have some seriously cool techniques at their disposal for analyzing engineering materials. They can visualize and analyze these materials’ grains, constituents, inclusions, and phases. Using contrasting methods can enhance the visibility of specific microstructural features, giving us a complete understanding of what we’re looking at. With the advancement of imaging technology, we can analyze these materials with even greater accuracy and detail.

Applications

This discipline is a powerful tool that has transformed many industries, helping to create more robust, more reliable, and safer products. It provides crucial insights leading to breakthroughs in materials development, quality control, and failure analysis by analyzing the microscopic structure of materials. With its wide range of applications, it is essential to the modern world, driving innovation and pushing the limits of what’s possible. Let’s discover some of the critical applications in different sectors:

1. Manufacturing and Engineering

- In the manufacturing and engineering industries, it is crucial to ensure the quality and reliability of metallic components.

- Metallographers examine the microstructure to identify any defects, such as inclusions or voids, which may compromise the structural integrity of a material.

- This knowledge allows manufacturers to make informed decisions regarding material selection, heat treatment processes, and production techniques.

- It aids in identifying the causes of component failure, enabling engineers to implement appropriate measures to prevent similar incidents in the future.

2. Automotive and Aerospace

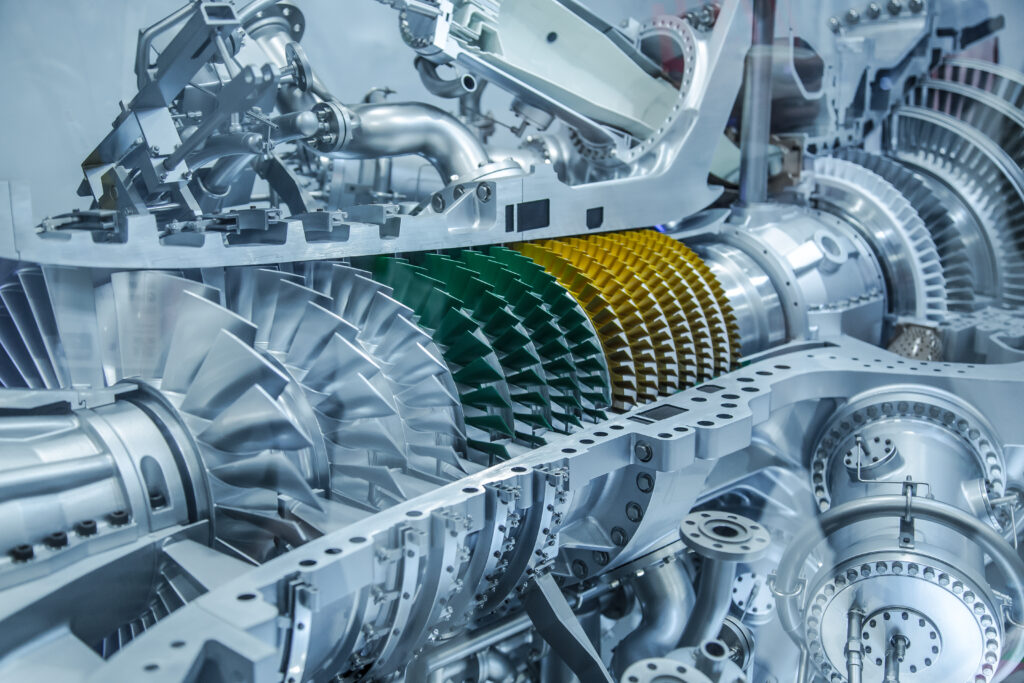

- It plays a vital role in ensuring the integrity of critical components in the automotive and aerospace sectors.

- Metallographers can detect potential issues such as grain boundary corrosion, fatigue cracks, or material degradation by analyzing the microstructure of engine parts, turbine blades, and other structural elements.

- This information guides manufacturers in optimizing materials and processes to enhance the durability and efficiency of these components.

- Ultimately, it helps improve vehicles’ and aircraft’s overall performance and safety.

3. Energy and Power Generation

- It is essential in the energy and power generation industries.

- It helps assess materials’ resistance to high temperatures, corrosion, and other environmental factors.

- Investigating microstructure is crucial in ensuring the performance of materials used in power plants, nuclear reactors, and renewable energy systems.

- The knowledge gained through metallography aids in the development of robust materials.

- It also ensures the long-term reliability and safety of energy infrastructure.

4. Research and Development

- In research and development, it is a fundamental tool for studying the structure-property relationships of engineering materials.

- By manipulating the microstructure through various processing techniques, researchers can tailor the properties of materials to meet specific requirements.

- It enables the characterization and understanding of these modifications, allowing scientists to optimize materials for specific applications.

- Whether it’s developing lightweight alloys for the aerospace industry or corrosion-resistant materials for marine environments, it plays a crucial role in advancing materials science.

Techniques and Analysis

Metallography encompasses various techniques and analysis methods for a more detailed microstructure examination. Let’s explore some of the critical processes and their applications:

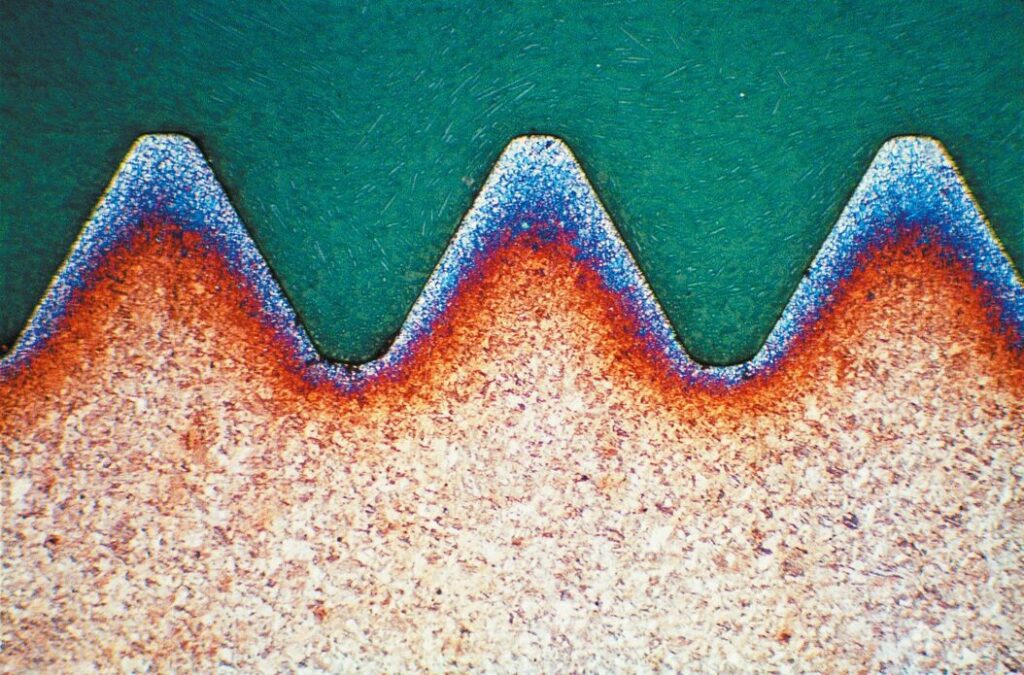

1. Inclusion Analysis

Inclusions, or non-metallic particles, can significantly impact the mechanical properties of materials. Metallographers employ various methods, including optical microscopy and statistical evaluations, to detect, classify, and analyze these inclusions. The results are often compared against recognized standards such as ASTM E45-18. By understanding the nature and distribution of inclusions, manufacturers can optimize material processing and minimize the risk of component failure.

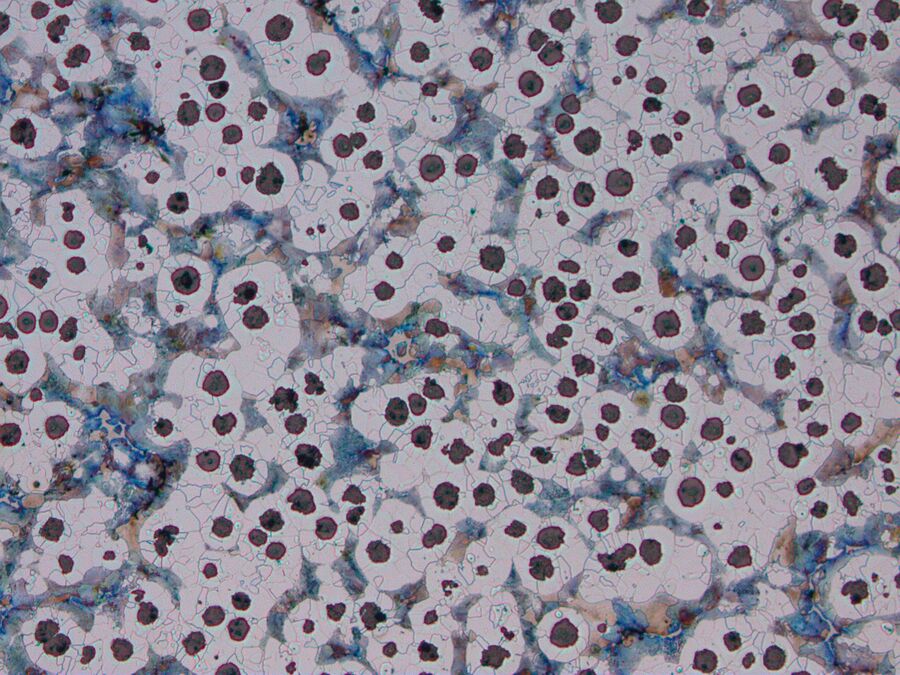

2. Graphite Nodularity Analysis

In ductile cast iron samples, the form, distribution, and size of graphite nodules can affect the mechanical and thermal properties of the material. Metallographers analyze these features according to standards such as ISO 945-1:2019. By quantifying and classifying the graphite nodularity, manufacturers can ensure the consistency and reliability of cast iron components, particularly in applications where high strength and flexibility are essential.

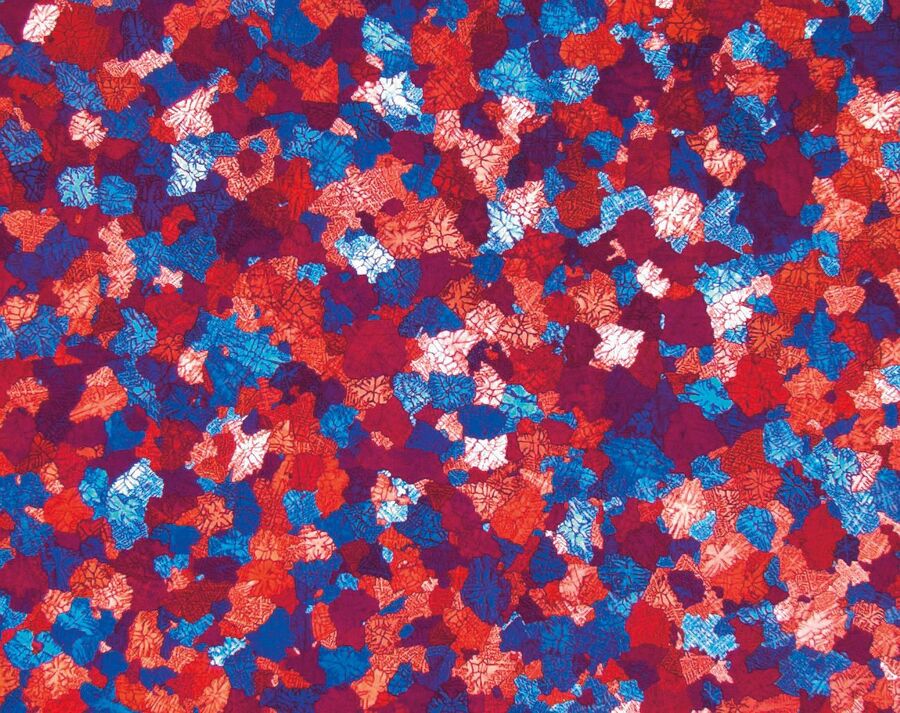

3. Grain Size Analysis

Grain size significantly influences the mechanical and physical properties of materials. Metallographers employ selective etching and image analysis techniques to measure and analyze grain size distribution. Standards like ASTM E112-13 and ISO 643:2019 provide guidelines for grain size measurement. By understanding the grain structure, manufacturers can optimize material properties, such as strength and toughness, to meet specific requirements.

4. Ferritic and Austenitic Grain Size Measurement

In steel materials, the grain size can affect mechanical properties, including strength and hardness. Metallographers use different standards to measure and characterize the grain size in steel samples. By quantifying the grain size, manufacturers can ensure consistent material performance and make informed decisions regarding heat treatment processes and alloying elements.

Conclusion

The fascinating discipline of metallography provides us with a window into the mesmerizing world of engineering materials and their properties. By delving into the microstructure of these materials, researchers and engineers can unlock the secrets to optimizing material selection, manufacturing processes, and product development. It is not limited to just one industry, but rather, its diverse applications can be found across a range of fields, from automotive to aerospace to energy to research. With technology advancing at a breakneck pace, metallography will continue to play a pivotal role in driving innovation and ensuring the reliability and performance of future materials and products.

Opti-Tech Scientific, a Canadian distributor of Metallographic Sample Preparation Equipment, is dedicated to supporting the metallography community with top-quality instruments and solutions. Their range of scientific equipment, including microscopes, laboratory furnaces, and metrology equipment, empowers researchers and manufacturers to conduct precise and accurate metallographic analyses. With the advancements in techniques and the availability of cutting-edge equipment, the field continues to evolve and contribute to the rise of materials science.

So, whether you’re exploring the microstructure of a new alloy or investigating the root cause of a component failure, metallography is your gateway to unlocking the secrets hidden within metallic materials. With its applications spanning across industries, it continues to shape the present and future of materials engineering. Embrace the power of metallography and discover a world of possibilities in the microscopic realm of metallic alloys.