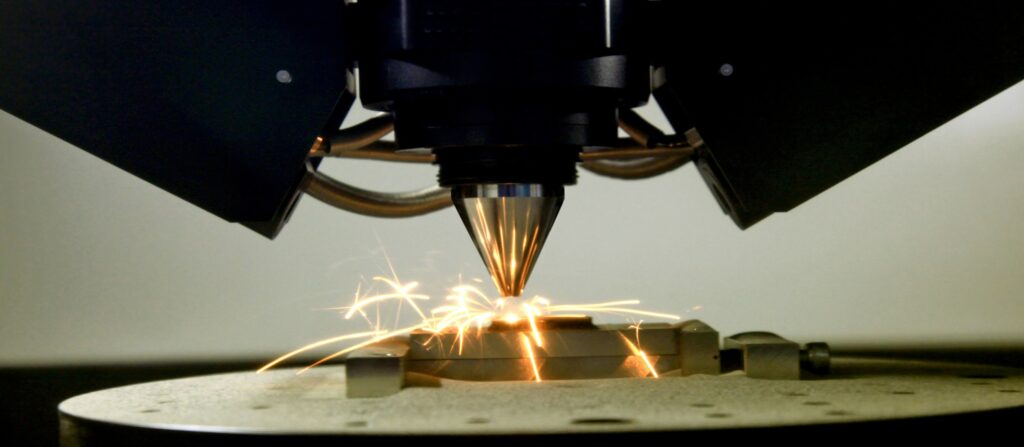

In a world where innovation is the key to staying ahead, additive manufacturing is a game-changer for the automotive and aerospace industries. This groundbreaking technology allows for the creation of parts and components layer by layer, opening up new possibilities for design, efficiency, and sustainability. It transforms traditional manufacturing methods, enabling the production of complex designs that were previously impossible or prohibitively expensive.

By reducing material waste and cutting down on energy consumption, additive manufacturing accelerates the development process and promotes environmental sustainability. As a result, both the automotive and aerospace sectors are witnessing a revolution, with additive manufacturing at the forefront, driving forward innovation and redefining the boundaries of engineering and design.

Why additive manufacturing is a big deal in cars and planes

In the automotive industry, additive manufacturing lets companies make parts that are lighter, stronger, and more complex than ever before. Imagine a car part made to fit perfectly, with no waste. That’s what additive manufacturing can do. It means enabling cars to be more fuel-efficient and have better performance. In the aerospace industry, it’s even more exciting. Planes and rockets can have parts that are impossible to make with old-school methods. Plus, making things faster and cheaper is always good when we’re talking about high-tech planes and space exploration.

One of the most exciting aspects of additive manufacturing is the ability to customise vehicles to a degree never before possible. Imagine ordering a car tailored precisely to your preferences, from the ergonomic design of the seats to the aerodynamic shape of the body, all made possible through additive manufacturing. Moreover, it’s not just about luxury; it’s about efficiency and sustainability. By reducing material waste and cutting down on the energy used in production, 3D printing is steering the automotive industry toward a more sustainable future.

Additive manufacturing in aerospace applications

In the aerospace sector, the stakes are sky-high, and additive manufacturing is proving to be an invaluable ally. Producing lighter, stronger components can significantly impact fuel efficiency and overall aircraft performance. Aerospace engineers are leveraging 3D printing to create parts with complex geometries that are difficult, if not impossible, to make using traditional methods.

But it’s not just about the parts themselves; it’s about the process. Additive manufacturing allows for rapid prototyping, speeding up the development cycle of new aircraft and enabling innovations to take flight sooner. This agility is critical in an industry where safety is paramount, and the pressure to innovate is constant.

Challenges and opportunities

espite its potential, additive manufacturing faces challenges such as high costs, technical limitations, and the need for specialised materials. However, as technology advances, these obstacles are becoming less formidable. The automotive and aerospace industries are investing heavily in research and development to overcome these hurdles, paving the way for wider adoption of additive manufacturing.

The future of innovative additive manufacturing

So, what does all this mean for us? It means that the future of manufacturing is here. Cars and planes are just the start. As technology continues to evolve, we can expect to see even more remarkable applications that will drive these sectors into a new era of design and production. The possibilities are endless, from medical devices to buildings, and even space travel.

Additive manufacturing is not just a fancy way to make things; it’s a revolution in how we think about making everything from cars to planes. With the integration of microscopes, particularly from Leica, into the inspection process, we ensure the highest quality of manufactured products. This step is crucial for identifying any imperfections at a microscopic level, thus guaranteeing superior product integrity. Similarly, our collaboration with Carbolite for sintering ovens further enhances our capability to deliver exceptional quality.

These partnerships allow us to refine the post-processing stages of additive manufacturing, ensuring that every component meets stringent quality standards before being deployed in automotive or aerospace applications. With companies like Opti-Tech Scientific Inc. providing the tools to see the world at a microscopic level, we’re equipped to drive auto and aerospace innovation further and drive manufacturing forward for continuously more advanced products.

At Opti-Tech Scientific Inc, our offerings are tailored to meet the diverse needs of various sectors, including research institutions aiming for groundbreaking discoveries and industrial organisations in pursuit of quality control solutions. For a more detailed exploration of our extensive range of product solutions and other metallography equipment, be sure to visit our website.