HYDROGEN GAS SAFETY SYSTEM 1

750 °C TO MAXIMUM TEMPERATURE

This system is suitable for use with either tube furnaces using a suitable work tube package or chamber furnaces using an A105 retort up to a maximum internal volume of 50 litres.

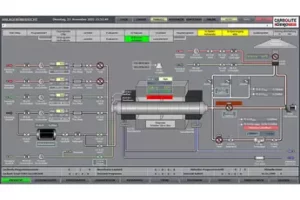

It is supplied with its control cabinet, off-the-gas burner and flexible pipes with fittings to connect directly to a gas atmosphere work tube package or chamber A105 retort.

The system automatically purges the work tube or chamber with nitrogen, ensures hydrogen is only introduced to the furnace above a safety temperature of 750 °C and provides an end purge of nitrogen. A nitrogen purge also occurs in the event of unplanned shutdowns.

Two adjustable flow meters allow hydrogen and nitrogen flow to be blended to suit the process. A monitored electrically heated gas ignitor ensures the hydrogen is fully consumed.

STANDARD FEATURES

- Over-pressure protection for the work tube or retort

- Excess flow (rupture) protection

- Purge timer

- Independent safety purge

- Supply gas monitoring

- Furnace temperature monitoring

- Electric ignitor

TECHNICAL DATA

- Control box dimensions (H x W x D): 440 x 430 x 490 mm

- Burner assembly dimensions (H x W x D):

650 x 300 x 335 mm - Power requirement: 300 W

HYDROGEN GAS SAFETY SYSTEM 2

ROOM TEMPERATURE TO MAXIMUM TEMPERATURE

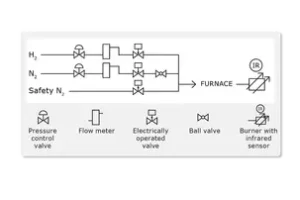

This hydrogen tube furnace system is based on the F-range and HTRH-range. It is designed to meet all required regulations for safely handling hydrogen gas.

Note: The system is only suited for clean processes. No outgassing of the samples must occur.

STANDARD FEATURES

- Full hydrogen operation for tube furnaces always in combination with a minimum of one inert gas

- Hydrogen from room temperature (RT) up to the maximum temperature

- Safety-related SPS with touch panel control

- Purging tank (N2)

- Tube materials up to 1100 °C: Quartz

- Tube materials up to 1800 °C: RCA

- Water cooled flanges

OPTIONS

-

- Sample thermocouple

- Fine vacuum pump

- High vacuum pump

- Second inert gas

- Cascade control